Our Sales staff can evaluate current operations, establish project expectations & goals working with your team to identify the scope of work. We provide budget project costs for your conveyor and material handling needs. Upon acceptance, conceptual layouts and equipment designs are generated. Cost analysis and firm pricing are established to meet your requirements. Our engineering team will work with you to design a complete supply chain system that will meet your strategic objectives. Our engineering packages include assembly drawings with bill of materials, pneumatic schematics and electrical control drawings with PLC programming documentation.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Material Handling Design Company, Services, Conveyor Engineering, Electrical, Pneumatic Controls

Taylor Material Handling & Conveyor can provide Turn-Key Systems –

Design, engineering and installation of material handling equipment, conveyors and controls are combined in one package to eliminate multiple points of contact. We are positioned to handle every step of a material handling project. Let us be your material handling experts.

Our team can provide economical solutions for installation, supervision or startup assistance working hard to meet your scheduling requirements. Our team has the experience, systems and methodology to provide Turn-Key Single Source Solutions.

-

Engineering & Consulting

-

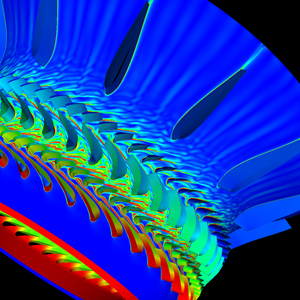

Simulation

Our simulations can graphically demonstrate equipment operation, how it interfaces with other equipment and personnel. Simulations are available for many of our products. Project Management – Each project is assigned to an experienced project manager who will guide the project from concept to completion. Our project managers ensure that every aspect of your system’s installation and integration will be complete, on-time and within budget. Once the project is approved, a plan of mile stones are developed and a schedule for installation is established. All work will be performed based on the agreed implementation plan.

-

Manufacturing

All types of equipment can be built by our fabrication shop to work with your unique application. These manufacturing methods include machining, fabrication and painting. Our fabrication department is efficient in production items, individual weldments and all types of custom designed fabrications. We are equipped fabricate metals including Stainless Steel, Mild Steel and Aluminum. The paint department applies all industrial enamels and two part epoxy finishes.

-

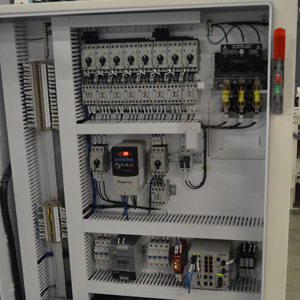

Electrical Control Systems

Complete electrical control systems designed to suit our broad range of material handling equipment. Electrical control systems can include PLC programming with HMI’s (Human interface unit’s)or Fieldbus systems with Profinet. Electrical sensors include photo eyes, proximity switches and limit switches. Safety control circuits include light curtains, safety mats, pull cord cables and push button switches.

We provide a full service of electrical controls specializing in machine and material handling automation. Special control applications can include Bar Code Sortation, Print / Apply Label Machines, Motion Weighing and Counting of Product.

Our systems will enable network controls, data collection and integration to production floor. Maintaining, servicing and supporting your industrial controls systems is essential to minimize downtime. We understand business needs and provide support options to meet them.

-

Pneumatic Control Systems

Complete pneumatic control systems are designed to complete our automated material handling equipment. Pneumatic control systems can provide air logic design using pneumatic piloted devices such as solenoid valves, limit switches and pressure switches. Operator interface is done with palm buttons, hand valves and foot pedals. Pneumatic control systems are a cost effective solution for most equipment compared to electrical PLC’s.

-

Field Installation

Our qualified installation crews are trained to provide quality, economical and on time installations. We can provide Non-Union or Union technicians to install the equipment we provide. We carefully select who we work with, ensuring quality customer service and results.

No project is too small or too large. We are committed to providing quality installations.

-

Project Start-Up, Training & Ongoing Technical Support

Involvement with the project extends beyond the installation stage. Our team remains on-site to start-up the system and train customer personnel with operation & maintenance procedures. Ongoing technical support is also available as required to ensure system performance and production expectations.

-

Inspection and Service of Existing Lift Tables

When your lift table is not working properly, SHIP IT TO US. We will assess the equipment and determine what repairs or part replacement is necessary. Don’t replace equipment when you can repair. Repairs can save money and reduce downtime.

-

Service Existing Conveyors and other Material Handling Equipment

Taylor Material Handling & Conveyor can service, rebuild or refurbish your existing equipment to meet the needs of upcoming challenges. Upgrades to existing equipment are more common now to utilize existing equipment at lower costs. Maintenance agreements are also available to provide regular scheduled maintenance for all types of equipment. Our plans range from simple inspections, lubrications, replace worn components to complete preventative maintenance programs.

We offer unlimited phone support during regular business hours (8:00am – 5:00pm EST Monday thru Friday) . Our service crews are equipped with the necessary tools and equipment to provide a variety of services. We are available for standard service calls during normal working hours (Monday – Friday 7:00am – 4:00pm), after hour calls from 4:00pm to 11:00pm and Weekends.

The above listed services can be provided with our Turn-Key packages or on an as needed basis from helping you troubleshoot a piece of equipment or assisting in machine upgrades.