Need an overhead ergonomic solution that offers more programmability and customization than a traditional hoist? View the G-Force and Easy Arm intelligent lifting devices from Gorbel, which enable operators to lift and maneuver naturally, as if the devices were an extension of their arms. They also offer a combination of pinpoint precision and blazing speeds that traditional lifting devices can’t provide. Taylor Material Handling & Conveyor is a distributor for these Gorbel products and for Cleveland Tramrail with over 50 years experience in custom factory and ergonomic solutions.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Overhead Lifting Solutions for the Factory and Warehouse – Ergonomic Lifting Equipment Specialists

Taylor Material Handling & Conveyor is a long-time trusted supplier of many types of overhead ergonomic lifting solutions including: vacuum lifting equipment, bridge cranes, monorails, jib cranes, gantry cranes, tooling support systems, and fall arrest equipment. There are many types of overhead lifting equipment, but they all share the same goal of safely lifting product and moving it efficiently and ergonomically from one point to another without damage to the product or the facility or injury to the worker. View our selection of name-brand selection below, for which we are authorized distributors/dealers. Call or email for a no-obligation discussion and a quote. We can meet with you at your location, if required.

-

Overhead Ergonomic Lifting Solutions

-

Vacuum Lifting Equipment

Taylor Material Handling & Conveyor offers a complete range of vacuum lifters and vacuum lifting equipment. Self-powered mechanical vacuum lifters, electric and air-powered vacuum lifters are all available in lifting capacities ranging up to 60,000 lb (26,600 kg) or more. TMH is a distributor for Anver, the top brand for ergonomic vacuum lifting equipment. We are also a Schmalz distributor. Rely on our over 50 years experience of custom material handling lifting solutions.

-

Bridge Cranes

Free standing bridge cranes are floor supported systems that do not put stress on the building’s overhead structure. Installation is more straight forward, and these cranes are also easier to relocate in the future. With ceiling mounted bridge cranes, supporting steel does not interfere with the handling operation. Ceiling mounted systems require a building with an adequate overhead structure to hang the crane. Taylor Material Handling & Conveyor offers a Gorbel, Cleveland Tramrail, and Demag bridge cranes, as an authorized distributor/dealer. Rely on our over 50 years experience in lifting solutions.

-

Monorails

We offer monorails with capacities from 150 to 4,000 lbs with linear movement and modular designs providing ultimate flexibility. They can be integrated into a total monorail system with extra track, curves, interlocks and switches. A Safe-Rail monorail is a hand-push transport and storage alternative to manual rehandling or product. Taylor Material Handling & Conveyor is a Richards-Wilcox, Demag, and Gorbel monorail distributor/dealer with over 50 years experience in material handling solutions.

-

Jib Cranes

We supply superb quality I-beam jib cranes which allow for easy rotation and optimal standard deflection of objects. This allows workers to position loads safely and easily. I-beam jib cranes are available in manual or motorized rotation are available from Taylor Material Handling & Conveyor, which is a Gorbel distributor/dealer with over 50 years experience in material handling solutions. Free standing I-beam jib cranes also have foundationless options to save you money.

-

Tooling Support Systems

Jib cranes, trolleys, and accessories for suspending light tools are available from Taylor Material Handling and Conveyor featuring Gorbel products. With Gorbel’s innovative rail technology and years of experience with overhead solutions, TMH offers complete solutions for the suspension of tools. The cornerstone of these tool solutions is the patented enclosed track design, which is engineered for easy movement. The cold rolled steel track keeps dirt and dust from settling on the rolling surface, allowing for smoother, more consistent easy movement of trolleys and tools than with an I-beam without cleaning or maintenance of the track. TMH is a Gorbel distributor/dealer with over 50 years experience in material handling solutions.

-

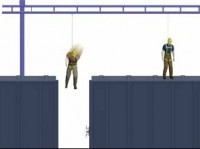

Fall Arrest Solutions

Gorbel’s fall protection systems (fall arrest) provides reliable and cost-effective overhead fall protection, reducing the risk of injury in elevated work environments. Choose between ceiling mounted systems or free standing systems to find the solution that’s right for your facility. Mobile application? Gorbel’s Ranger Mobile Anchor is the portable fall arrest system you’ve been looking for. This towable fall protection anchor is ideal for maintaining and repairing aircraft, industrial equipment or heavy machinery, or for any elevated application that demands mobility. Taylor Material Handling and Conveyor is proud to distribute Gorbel fall protection equipment with over 50 years experience in ergonomic solutions.

-

Gantry Cranes

Gorbel’s fixed and adjustable height steel gantry cranes provide an economical way to lift materials anywhere in a facility. Their wheels feature enable you to move the gantry around your facility easily. This is more cost-effective lifting solution for areas of infrequent lifts than a more expensive permanent structure. The heavy duty end frame design with square tubing uprights, knee braces, and channel base provides stable lifting and movement. Taylor Material Handling and Conveyor is proud to be a distributor/dealer for Gorbel gantry cranes with over 50 years experience in material handling solutions.