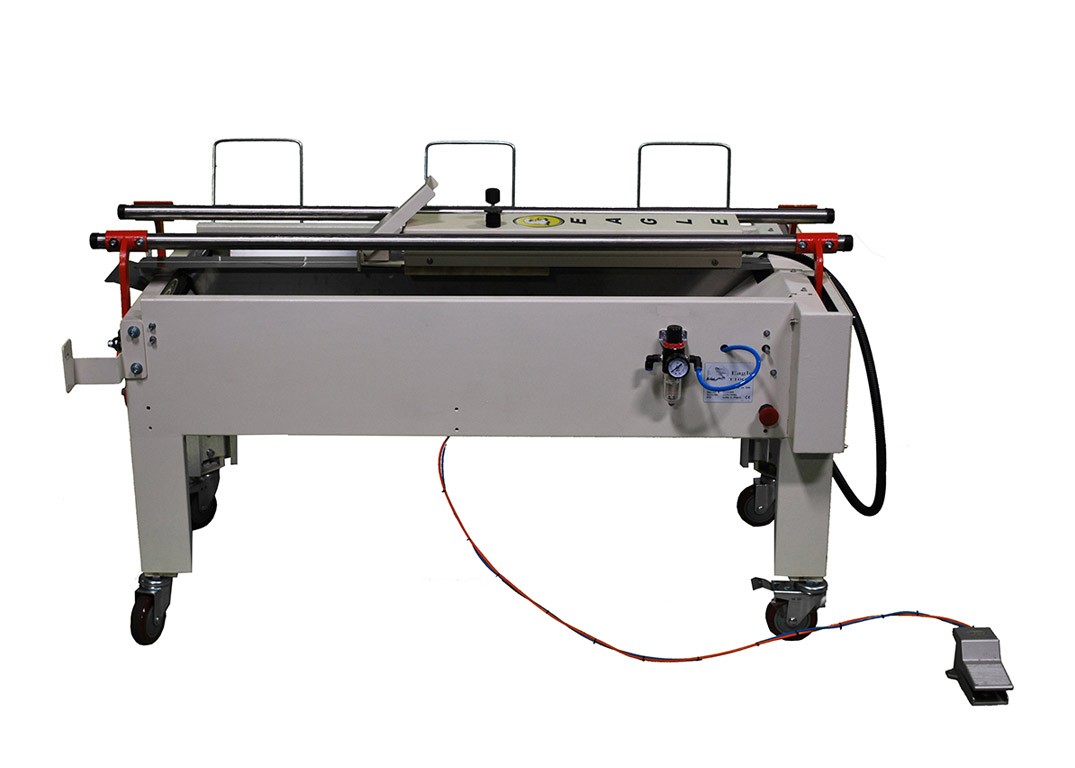

- Holds Carton in Location for Filling

- Semi-Automatic Carton Traverse

- Folds Bottom Flaps

- Foot Pedal/Push Button Activation

- Locking Casters

- Add on Unit Easily Attaches to an Eagle T500

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Case Erectors and Sealers

Carton Sealing Systems, Strapping Machines, Stretch Wrappers, Scale Systems

Taylor Material Handling & Conveyor is an authorized Eagle, Eastey, Orion Packaging, and Fairbanks Scale packaging machine distributor/dealer. Through the years, our packaging machines have been used in different types of industries. Some of these include automotive, toy wood, steel, medical, golf, food processing and many more. Our machinery’s quality and pricing are the best in the market that range from the Eagle T100SM that can tape a very small package to the Eagle T500 with automatic top flap folders. Our stretch wrappers have proven that they have the lowest cost per pallet wrapping capability available. To conclude, these machines are researched and studied to ensure they will be the best value available. For case erectors, strapping machines, carton sealing systems, stretch wrappers, and scale systems, contact us today for a no-obligation discussion and a quote. We can meet with you at your location, if required. Thank You from the TMH team.

Case Erectors

-

Model T10CF Case Erector

-

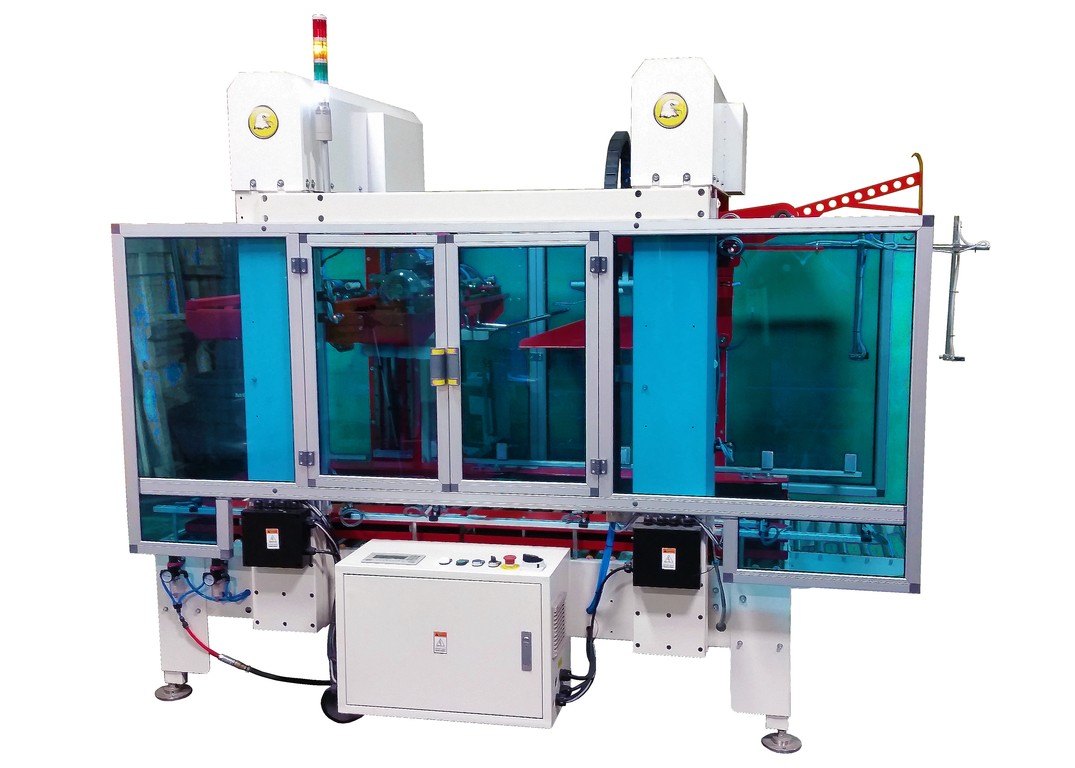

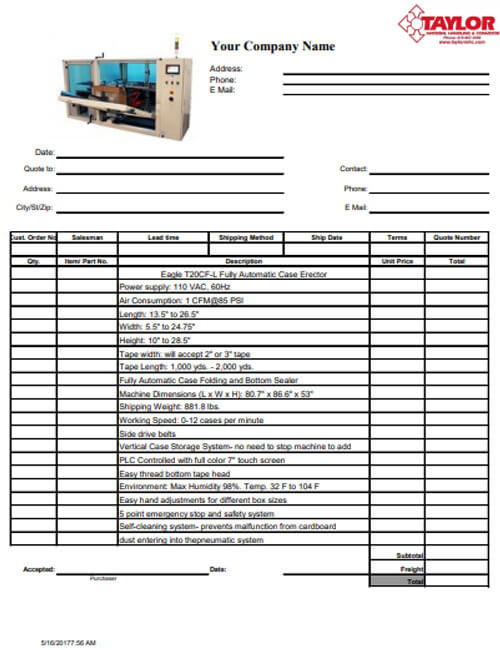

Model T20CF Automatic Case Erector

The Eagle T20CF constructs and seals the carton bottom cover during operation. Total process time per carton is only 3 seconds! With the vertical storage system, cartons can be added at any time without stopping the machine. The Eagle T20CF offers increased productivity and is suitable for various carton sizes and can be manually adjust in under 2 minutes.

- Power supply – 110VAC/60Hz

- Air Pressure – 85 psi

- Tape Width – 2″ and 3″

- Working Speed – 0 to 10cases/min

- Case Size Length – 11″ to 20.5″ Width –7″ to 11″ (base carton size must meet the following requirement: 24″ > W/2+H > 11″ L change scope 5.75″)

- Machine Dimension (W x L x H) – 86.6″ x 80.7″ x 53″

- Machine weight – 881.8 Lbs

- Environment conditions Humidity – 98%, Temperature –32ºF to 104ºF

Strapping Machines

-

Model SP-11 TableTop Strapper

The Eagle SP11 is eco-friendly through utilization of two direct drive 24VDC motors. This eliminates the need for a complex belt and pulley system and provides for nearly silent operation. Strap tension is controlled electrically, eliminating the need for a manual spring-based hand crank system. Just like the Eagle 100, the Eagle SP11 is height adjustable, includes a stainless steel table top, and has a safety switch that cuts power while the lid is open to protect the operator.

- Dual direct-drive 24 volt motors

- “Silent” operation

- Quad locking casters

- Adjustable leg height

- Electronic tension control

- Stainless steel table top

- Safety Switch

- Eco-friendly

-

Model 800 Automatic Arch Strapper

The Eagle 800 is an enhanced automatic strapping machine for wide straps (9mm – 12mm). With its enhanced features, the Eagle 800 has the best price to performance ratio of products in its class.

- Self-Threading

- Short Feed Sensor

- Strap End Ejector

- Loop Ejector (Anti-Jam Feature)

- Electronic Tension

- Stainless Steel Table Tops

- Manual Push Button, Automatic Table Switch or Foot Switch

-

Model 710 Auto High-Speed Strapper

The Eagle 710 is an innovative world-class high-speed automatic strapping machine capable of using 5mm, 6mm, 9mm or 12mm polypropylene strap. It offers optimal performance, highest speed, easiest maintenance and the most cost effective solution in its class. The Eagle 715 & 702 series use the latest DC brushless motor technology to provide the highest level of accuracy and reliability on the market. All motors are German-made. The strapping head has no belts, clutches or pulleys. It is designed with up-to-date technology with minimal moving parts. With 30% fewer parts, the Eagle 715 & 702 series strapping machines require fewer adjustments, less maintenance, and has fewer wear components.

- LCD Screen Display

- Self-Threading

- Low and High Tension Settings

- Loop Ejecter for Jam-Free Operation

- Waist High Coil Changer with Quick Release

- Tool-Free General Maintenance

-

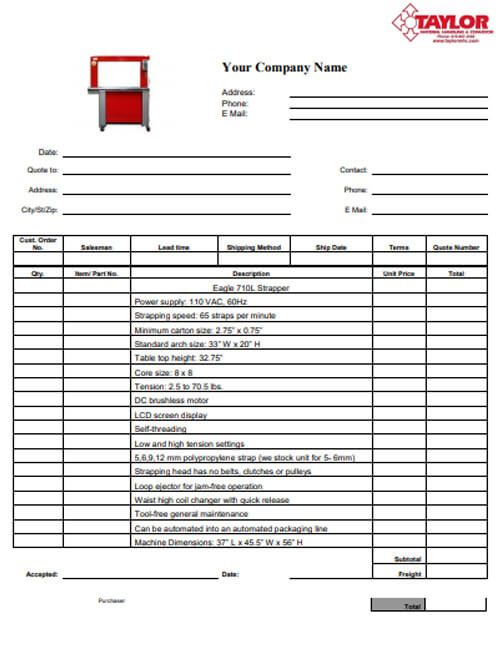

Model 710L Auto High-Speed Strapper

Eagle 710L is an innovative world-class high-speed automatic strapping machine capable of using 5mm, 6mm, 9mm or 12mm polypropylene strap. The Eagle 710L comes equipped with industry standard features and creative user friendly designs. The Eagle 710L offers the optimal performance, high speed, easy maintenance and a cost effective solution for your package strapping needs. The Eagle 715 & 702 series use the latest DC brushless motor technology to provide the highest level of accuracy and reliability on the market. All motors are German-made. The strapping head has no belts, clutches or pulleys. It is designed with up-to-date technology with minimal moving parts. With 30% fewer parts, the Eagle 715 & 702 series strapping machines require fewer adjustments, less maintenance, and has fewer wear components.

- LCD Screen Display

- Self-Threading

- Low and High Tension Settings

- Loop Ejector for Jam-Free Operation

- Waist High Coil Changer with Quick Release

- Tool-Free General Maintenance

- Features a large arch opening of 33” x 20” (W x H)

Carton Sealing Systems

-

Eastey Case Sealers

Eastey’s case tapers are a cost-effective top and bottom case taper designed for large run case sealing. These case tapers feature self-centering side rails, a rugged bottom belt drive, and heavy-duty mast that easily adjusts to handle a variety of case sizes. Eastey offers the durability, versatility and reliability that you have come to rely on from Eastey. The system’s unique and simple design has proven to be one of the most reliable case tapers on the market today, keeping production and maintenance efforts to a minimum and providing fast and efficient alternatives to hand taping.

-

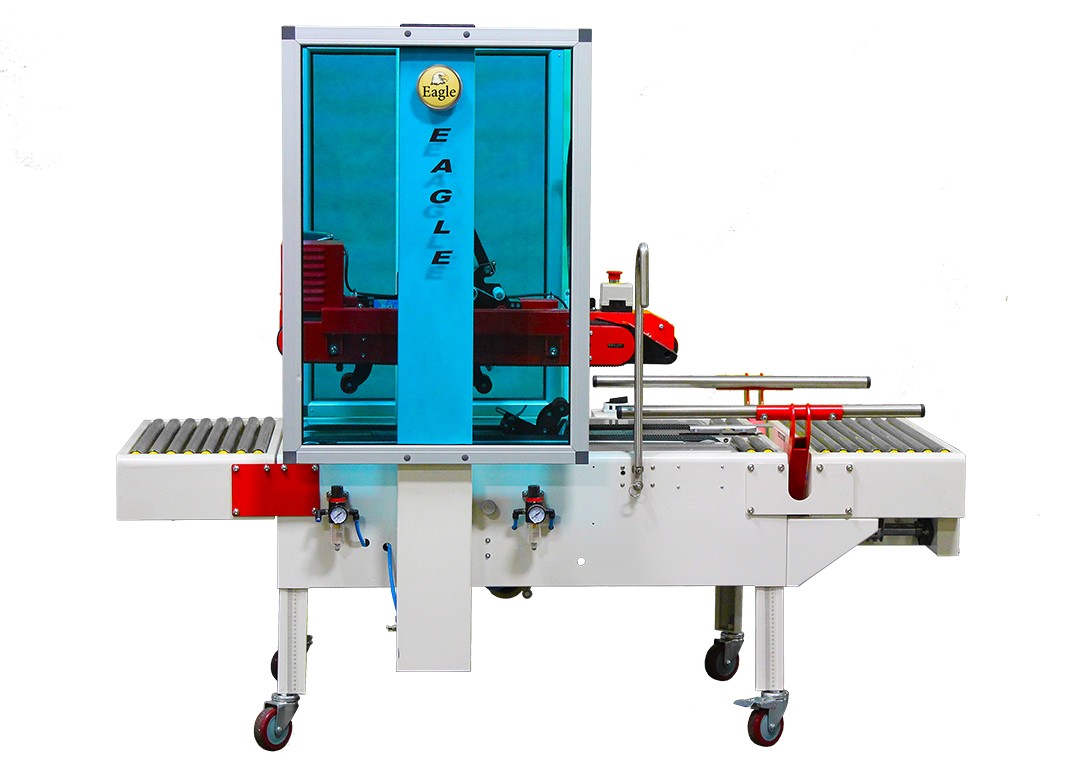

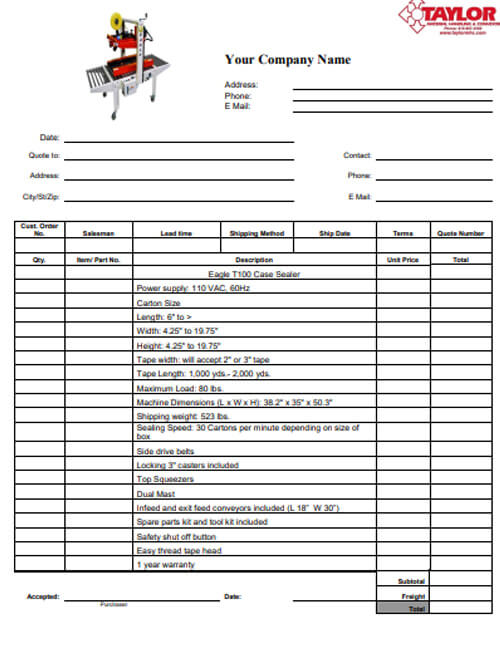

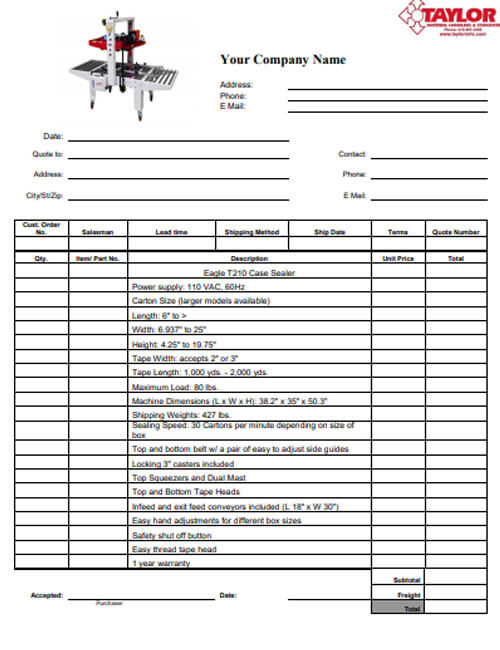

Model T100 Uniform Carton Sealer with Side Drive Belts

The Eagle T100 is the #1 Selling Eagle Carton Sealer! Best suited for medium volume production. Side belt drive ensures proper carton sealing even with cartons that are short in height, but have an extended length. Tape head can accept 2”and 3” tape with simple adjustments.

- Side Drive Belts

- Locking Casters

- Top Squeezers

- Dual Mast

- Top & Bottom Tape Heads

- Extension Roller Tables

-

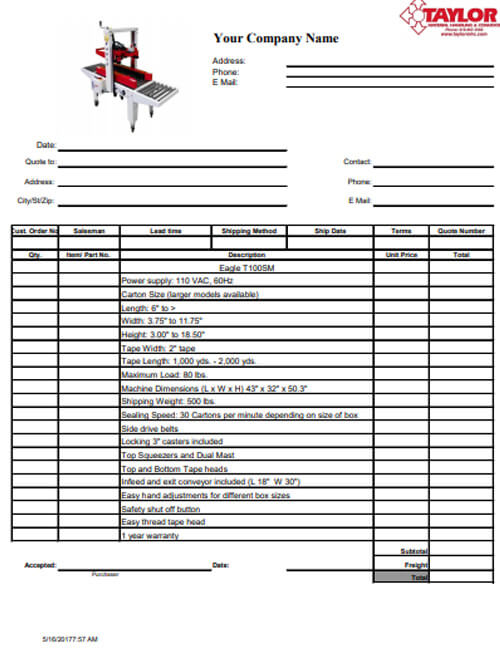

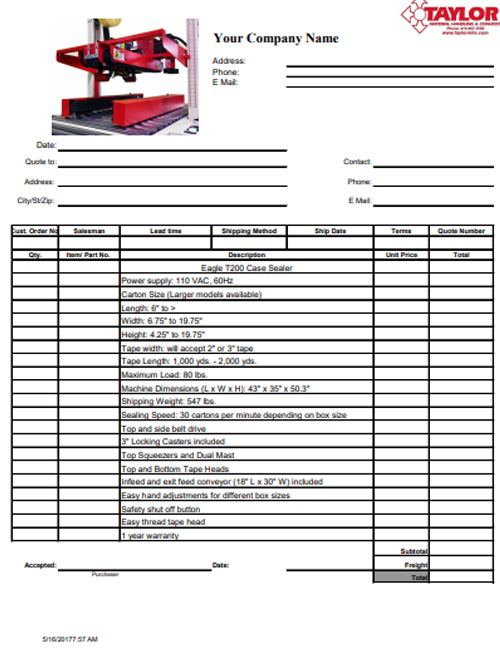

Model T200 Automatic Carton Sealer with Top & Side Drive Belts

The Eagle T200 takes the rigidity and simple design of the Eagle T100 and adds a set of top belts to stabilize tall, narrow cartons for proper sealing.

- Top & Side Drive Belts

- Locking Casters

- Top Squeezers

- Dual Mast

- Top & Bottom Tape Heads

- Extension Roller Tables

-

Model T210SS Stainless Steel Uniform Case Sealer With Top & Side Drive Belts

- Stainless Steel

- Top & Bottom Drive Belts

- Locking Casters

- Top Squeezers

- Dual Mast

- Top & Bottom Tape Heads

- Extension Roller Tables

- Ideal for wide cartons

-

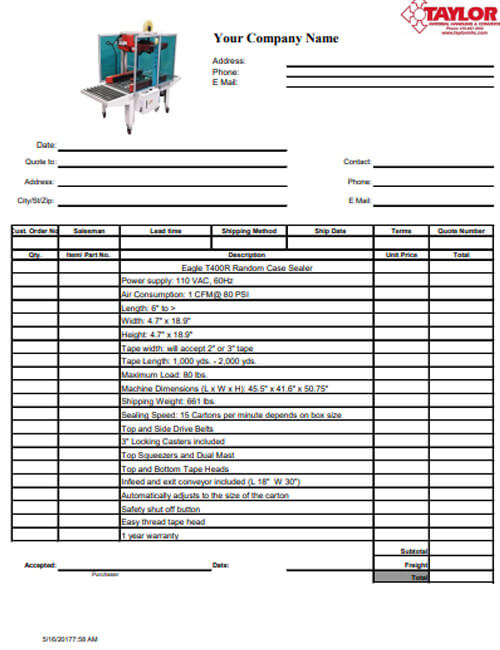

Model T400R Random Carton Sealer with Top & Side Drive Belts

- Top & Side Drive Belts

- Locking Casters

- Dual Mast

- Top & Bottom Tape Heads

- Extension Roller Tables

- Automatically adjusts to the size of the carton within the parameters.

-

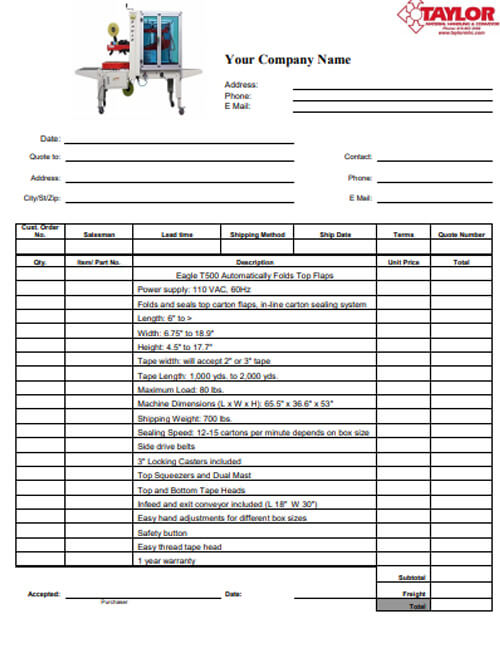

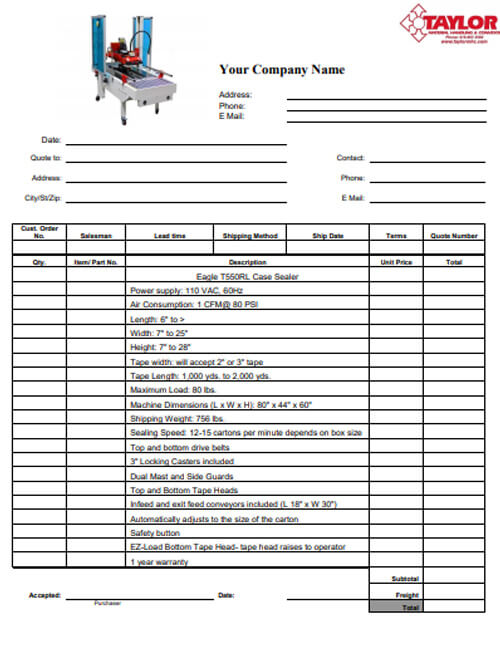

Model T550RL Random Carton Sealer with Top & Side Drive Belts

- Top and bottom drive belts

- Locking casters

- Adjustable height

- Dual mast, double screws

- Top and bottom tape heads

- Extension roller tables are standard

- Easy change bottom tape head

- Tape head compatible with 2” and 3”

-

Model T600RA Automatic Carton Sealer

- Fully Automatic

- Top & Side Drive Belts

- Locking Casters

- Dual Mast

- Top & Bottom Tape Heads

- Extension Roller Tables

- Automatically adjusts to the size of the carton within the parameters.

Stretch Wrappers

-

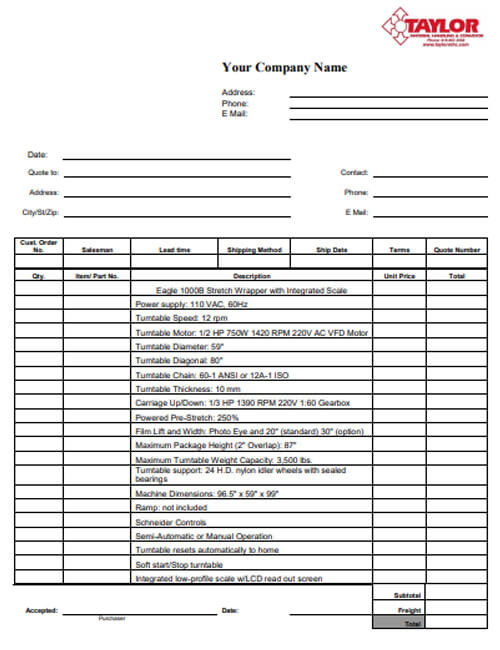

Model 1000B Semi-Auto Pallet Wrapper

- Semi-Automatic or Manual Operation

- Simplified control panel for easy operation

- Automatic Load-Height Sensor (ALHS)

- Powered Pre-Stretch (250%)

- Turntable Resets Automatically to Home Position

- Soft Start/Stop Turntable

-

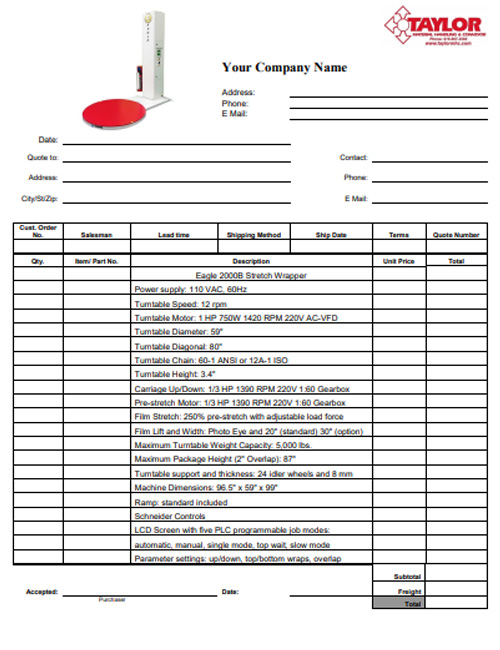

Model 2000B Stretch Wrapper

The Eagle 2000 series stretch wrapper features a powered pre-stretch unit to maximize film efficiency. Using an electronic photo eye, the Eagle 2000 automatically recognizes load height and adjusts carriage travel to create an effective wrap cycle.

The turntable offers a soft start and soft stop feature to ensure gentle handling of the load being wrapped. The turntable resets itself automatically upon completion of each load.

The available features provide for increased production and a cost per load savings that can easily justify owning an Eagle 2000 series stretch wrapper.

-

Model 2000EB Extended Base

The Eagle 2000 series stretch wrapper features a powered pre-stretch unit to maximize film efficiency. Using an electronic photo eye, the Eagle 2000 automatically recognizes load height and adjusts carriage travel to create an effective wrap cycle.

The turntable offers a soft start and soft stop feature to ensure gentle handling of the load being wrapped. The turntable resets itself automatically upon completion of each load.

The available features provide for increased production and a cost per load savings that can easily justify owning an Eagle 2000 series stretch wrapper.

-

Model 2000BE Extended Mast

The Eagle 2000 series stretch wrapper features a powered pre-stretch unit to maximize film efficiency. Using an electronic photo eye, the Eagle 2000 automatically recognizes load height and adjusts carriage travel to create an effective wrap cycle.

The turntable offers a soft start and soft stop feature to ensure gentle handling of the load being wrapped. The turntable resets itself automatically upon completion of each load.

The available features provide for increased production and a cost per load savings that can easily justify owning an Eagle 2000 series stretch wrapper.

-

Model 2000EBT Extended Base and Mast

The Eagle 2000 series stretch wrapper features a powered pre-stretch unit to maximize film efficiency. Using an electronic photo eye, the Eagle 2000 automatically recognizes load height and adjusts carriage travel to create an effective wrap cycle.

The turntable offers a soft start and soft stop feature to ensure gentle handling of the load being wrapped. The turntable resets itself automatically upon completion of each load.

The available features provide for increased production and a cost per load savings that can easily justify owning an Eagle 2000 series stretch wrapper.

-

Model 2000F Fully Automatic Stretch Wrapper

The Eagle 2000 series stretch wrapper features a powered pre-stretch unit to maximize film efficiency. Using an electronic photo eye, the Eagle 2000 automatically recognizes load height and adjusts carriage travel to create an effective wrap cycle.

The turntable offers a soft start and soft stop feature to ensure gentle handling of the load being wrapped. The turntable resets itself automatically upon completion of each load.

The available features provide for increased production and a cost per load savings that can easily justify owning an Eagle 2000 series stretch wrapper.

-

Model R2B2 Mobile Stretch Wrapper

The Eagle R2B2 is a versatile mobile stretch-wrapping robot perfectly suited for warehouses with limited space.

- Pro-Face Touch Screen HMI

- PLC Controlled

- Soft Start/Stop

-

Orion Flex Series Stretch Wrapper

Flex A models eliminate the need for operators to attach and cut the stretch film. Simply place the pallet load on the machine, and pull a lanyard switch while backing away. The machine will perform the entire wrap cycle automatically without the need for an operator to tie the film tail to the load at the beginning of the cycle, and detach it at the end. This will greatly impact the efficiency of your stretch packaging operation by keeping your operators busy with other tasks while the machine is wrapping.

-

Orion Flex RT Series Stretch Wrapper

The RT automatic stretch wrapping system is the fastest way to boost your end-of-line packaging efficiency by eliminating the need for operators to manually attach the film tail to the load, then cut and secure the film tail at the end of the cycle. The RT stretch wrapper automatically performs these functions so your operators simply place the load, pull a handing lanyard to start the cycle, and attend to other duties. When they return the load is securely wrapped and ready to be removed.

-

Orion FA Series Stretch Wrapper

The Orion FA is unique in the marketplace as it offers Category 2 Safety Rating as standard equipment, not an option. As part of Category 2 Safety Rating you’ll find full surround 8 foot high steel mesh fencing with interlocked access points as well as infeed and exit light curtains with electronic muting.

-

Orion MA Rotary Tower Automatic Stretch Wrapper

Fully automatic stretch wrapping systems from Orion all share a heritage of quality and long term reliability. Orion engineers its automatic systems with high quality components, state of the art electronics and plenty of heavy gauge structural steel for machines that operate at maximum efficiency year in and year out. Whether you need the small footprint of the FA system, or the flexibility of the MA line, Orion has the automatic stretch wrapper that will meet your budget and your requirements.

-

Orion CTS Conveyorized Twin Station Stretch Wrapper

The newly redesigned Orion CTS is a Conveyorized Twin Station stretch wrapping machine designed to increase fork lift efficiency and reduce load handling times by providing a powered conveyor turntable and a gravity conveyor section used as a staging platform for wrapped loads waiting to be picked up.

-

Orion Axis 6-Sided Automatic Stretch Wrapper

In certain industries, especially printing, total six-sided protection of pallet loads is desired for total product protection and to “lock” the load effectively to the pallet. Steel or poly strapping is commonly used, however many customers would like to eliminate the high cost, high maintenance and recycling issues of strapping.

Scale Systems

-

IM 6000 Scales

The IM 6000 In-Motion System is designed to make package weight information easy to collect and process. The system is available in many different lengths, widths and speeds for application flexibility and ensured compatibility with existing conveyor lines.

-

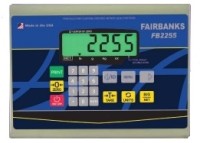

FB 2255 Scales

Fairbanks’ FB2255 Series Digital Instrument is a reliable choice for any industrial weighing application, from warehousing to general food processing. For batching and filling operations, system integration is easy — simply add a fieldbus accessory, such as PROFIBUS-DP, Ethernet / IP or DeviceNet. The FB2255 is also designed for convenient wireless operation with the aid of optional Bluetooth® wireless technology accessories.

- +Product Literature

- +Application Photos/Videos