Tabletop Conveyors are designed as a pre-engineered stock program. These conveyors can be built for strict clean room conditions or for use in a rugged shop floor environment. Our fully adaptable tabletop conveyors can be designed for a variety of applications including: transporting, merging, diverting, or accumulating products, and can accommodate a wide range of processing requirements including product filling, weighing, labeling, and production inspection.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Package Conveyors, Product Handling Conveyors

MCE Distributors, Re-Flow Accumulation Tables, Case Diverters, Turners

Taylor Material Handling & Conveyor offers a complete line of product and package handling conveyors. These conveyors optimize the packaging process and an easy solution to carrying boxes and bags between workstations and equipment. Our packaging conveyors can be integrated to meet the needs of your specific application and equipped with a number of safety, sanitation, sorting, diverting, and mobility options to help you get the exact solution needed. Let Taylor Material Handling & Conveyor guide you to the correct solution for your product and packaging application today. Call or email with any questions.

-

TableTop Conveyors

-

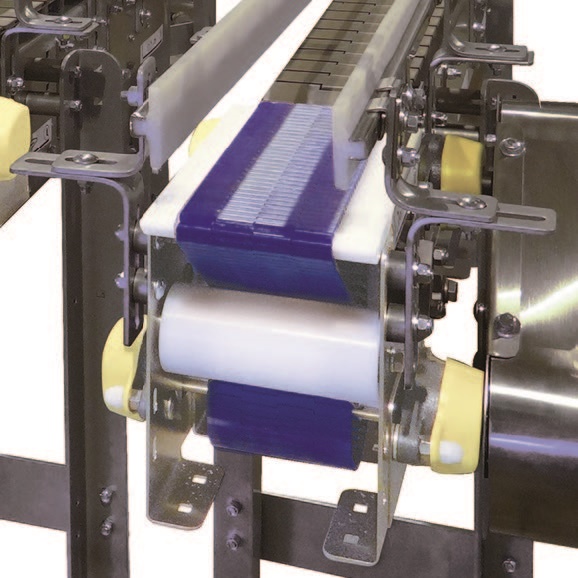

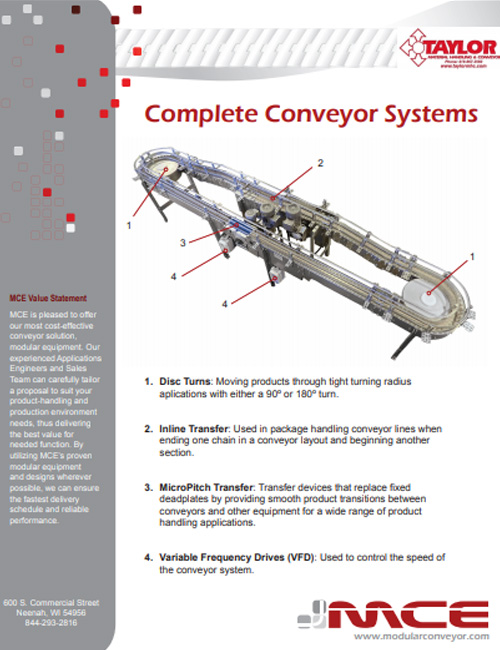

MicroPitch Transfer

MicroPitch Transfers feature standard designs that can be added to any of our standard conveyor types. These transfer devices replace fixed dead-plates by providing smooth product transitions between conveyors and other equipment for a wide range of product handling applications. They are especially effective with unstable or irregularly shaped products that can hang-up when transferring between conveyor sections and other packaging machinery.

-

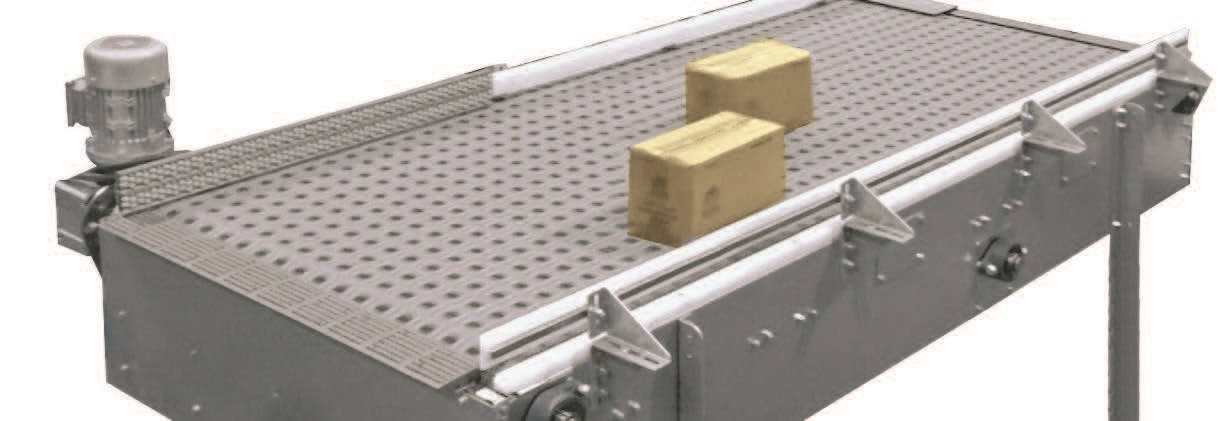

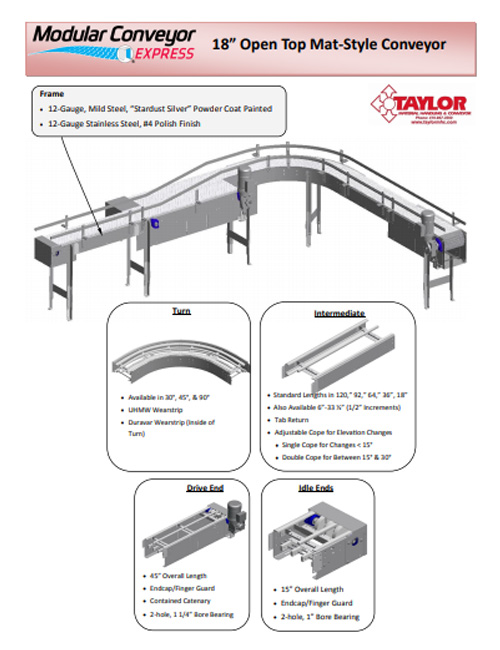

Mat-Style Conveyor

Mat-Style conveyors provide long life and high impact resistance. The sprocket driven Thermoplastic belts ensure positive tracking while providing quiet, smooth, trouble-free performance. A versatile conveyor line, these conveyors can handle flexible packaging, plastic containers, cartons, cases, and bundles.

-

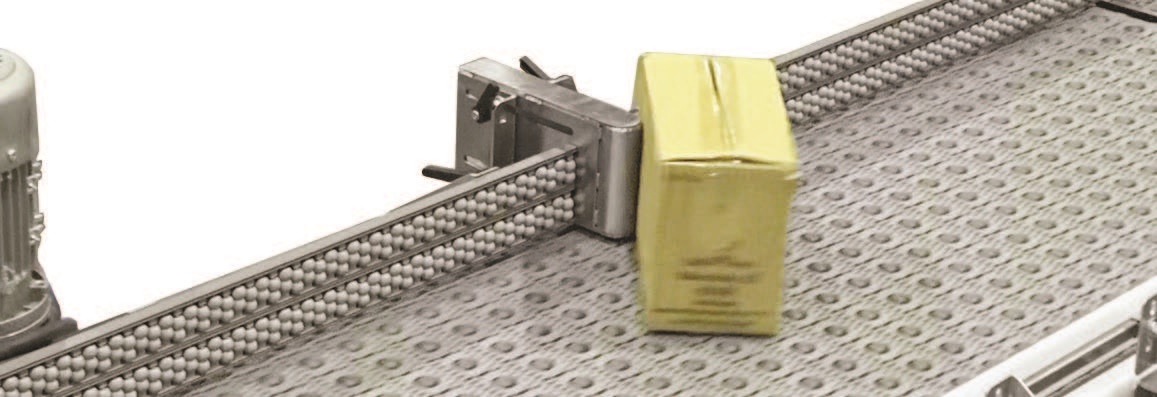

ARB Case Diverter

ARBTM Case Diverters divert packages from 1:2 lanes without interrupting product flow. Typical applications include rejecting product from the production flow on demand and dividing production output between parallel downstream operations. The system requires no hardware mounted above the conveying surface, no overhead structure to interfere with access to products, no change parts, and no mechanical adjustments.

-

ARB Case Turner

ARBTM Case Turner provides simple, effective 90º rotation of cases, totes, and rigid packages while maintaining product flow. This system requires minimal adjustment between packages and absolutely no change parts. The modular design saves time through quick installation and simple, efficient reconfiguration of existing production routes.

-

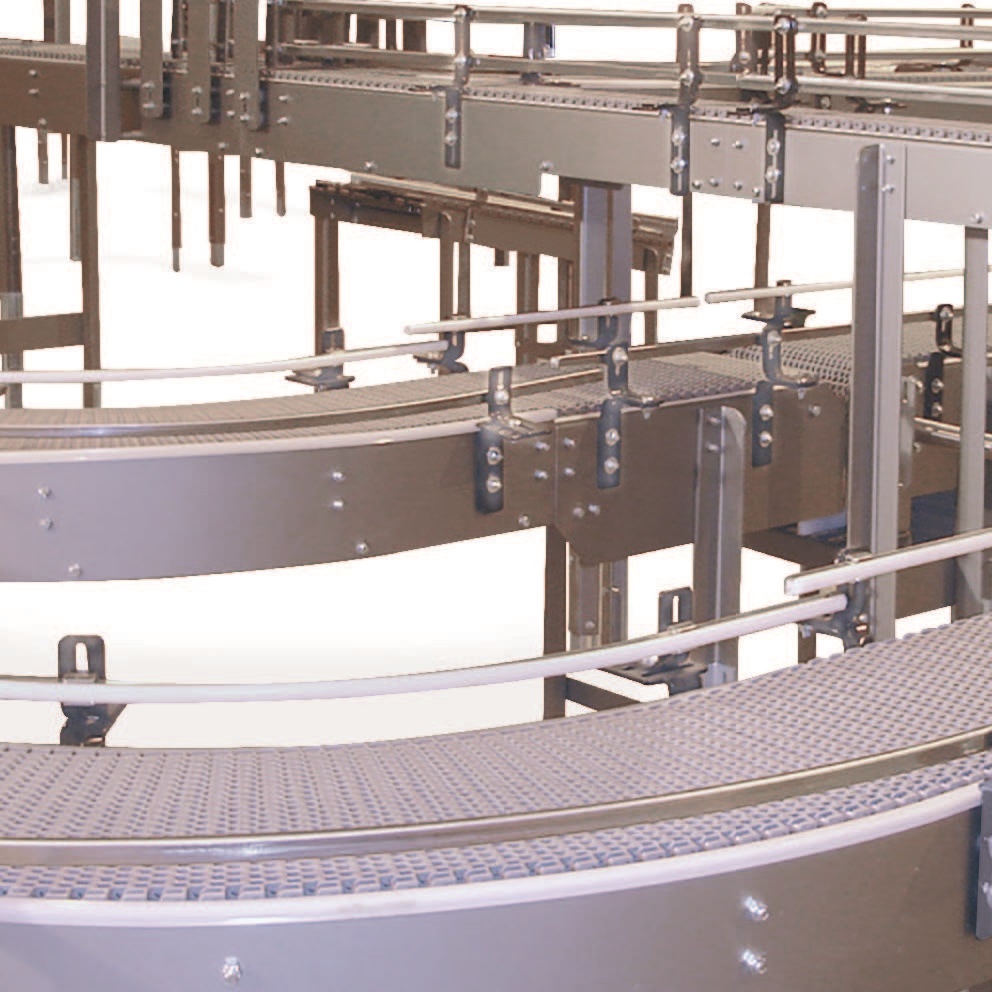

Re-Flow Accumulation Table

The Re-Flow Accumulation Table occupies a small footprint, while delivering large storage capabilities. The unique single-filing concept ensures smooth jam-free combining of products. The re-circulation design relieves product back pressure in the combining area and aids in overall accumulation pressure relief.

-

Divert Gate

The DIVERT GATE is bolt-on assembly, new to the product line, and provides one to two and one to three lane divert operation. The units have adjustable guide rail openings as well as elevation adjustment.

-

Rapid Rail

The new patent-pending RAPID-RAIL™ is engineered to simplify changeovers on the packaging line. RAPID-RAILTM offers a single point, easy-to-use hand adjustment of guide rails to accommodate multiple package sizes on the same piece of equipment. Several points along the conveyor, over a long distance, can be controlled from one location on the line.

-

Side Gripper

The Gripper Elevator has the advantage of securely elevating or lowering product using very little floor space. Side grippers firmly but gently grasp the products traveling in line with continuous transport through the elevation change and a seamless discharge onto the take-away conveyor.

-

Rotary Table

Rotary tables enable the collation and accumulation of products from conveyor lines and packing areas creating a buffer zone on a low speed line and also providing accumulation at the end of a production line. Ideal for areas that are not large enough or not suitable for an automated system.

- +Product Literature

- +Application Photos/Videos