Slider bed belt conveyors remain the most popular of all powered conveyors, providing an economical means of transporting goods for packing, testing, inspecting and various assembly line operations.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Belt Conveyors

Roller Bed Belt, Slider Bed Belt, Trough Bed Belt

Belt conveyor systems are some of the most widely used industrial equipment in any production setting. Belt conveyors are used for transporting good and materials, for automating assembly and processing, for shipping and packing, and more. Taylor Material Handling & Conveyor has the “right” belt conveyor solution for your unique application. Call us for a no-obligation consultation.

10 YEAR WARRANTY

At Dorner, all of the Belt and Sanitary conveyor designs are engineered and tested to ensure trouble free performance and reduce the cost of ownership. In this way, Dorner can offer every customer an Industry Leading Warranty. No other company in the industry offers a longer warranty. A 10 year limited warranty to the original purchaser against defects in material and workmanship under normal use, proper maintenance and cleaning. We will repair or replace the defective parts. Normal wear is not warranted. Dorner is not responsible for labor, freight or duties associated with the replacement of defective parts. Unauthorized modifications to the equipment or using non-Dorner supplied replacement parts shall void the warranty. Equipment manufactured by others is covered by the original manufacturer’s warranty.

Dorner does not warranty for merchantability or fitness of a particular purpose. Dorner does not warranty loss or damage to equipment, product, production, income, or profits and is not liable for direct, incidental, indirect, special or consequential damages, or any damages to persons or property.

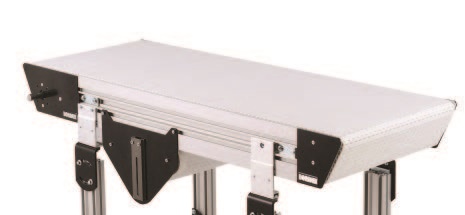

Slider Bed Conveyors

-

700 SB

-

700 BSB

Model 700BSB features a box style slider bed which offers a smooth work surface, ideal for workers stationed beside this conveyor. The 700BSB is an economical choice for tasks such as packing, testing and inspecting.

-

450 BOS

Model 450BOS slider bed belt conveyor is one of the most popular and common means of transporting goods for packing, testing, inspecting and a variety of assembly line operations. 450BOS features a box style slider bed, ideal for workers stationed alongside the conveyor.

-

Model 150

This is a standard duty low profile conveyor with an extremely shallow frame depth and presses in drive bearings, resulting in a drive width from 1″ to 4″ narrower than other slider beds. Typically used in tight fit applications to carry a variety of lightweight packages and parts.

-

Model 250

This is a heavy duty low profile conveyor that can be used when longer runs are required while maintaining narrow widths. Drive and bearing configuration is designed to carry more weight than the Model 150. Used in a variety of applications where limited space is a factor.

-

2200 Series Belt Conveyors

2200 Series low profile, high performance fabric and modular belt conveyors feature a high speed nose bar transfer option, a durable single piece frame design, universal T-slots, and a wide range of belting and guiding options.

-

3200 Series Belt Conveyors

3200 Series heavy duty, low maintenance conveyors that are ideal for medium to heavy sized parts, precision applications, bulk handling and both automated and manual assembly. Available in both fabric and modular belts, 3200 Series conveyors are designed for high speeds, long runs and up to 4 curves per conveyor.

-

200 Standard Duty

This is an economical shallow frame conveyor. The shallow frame is designed to fit into tight spaces other slider beds can’t. It’s built for low maintenance operation in shorter and narrower light duty production and packaging operations.

-

210 Medium Duty

This shallow frame large drive pulley (8″ Diameter) conveyor is versatile enough to get into tight spaces and durable enough for applications up to 36″ wide and 100′ long. It is built for low maintenance operation in medium duty production, assembly and packaging operations.

-

220 Medium-Heavy Duty

This heavy duty, deep frame slider bed is built for low maintenance and extended use in virtuallyany manufacturing environment. This sturdy, solid conveyor is designed for longer, wider and heavier weight slider bed applications.

-

221 Heavy Duty

This heavy duty, deep frame slider bed is built for low maintenance and extended use in virtually any manufacturing environment. This sturdy, solid conveyor is designed for longer, wider and heavier weight slider bed applications.

-

301 Standard Duty V-Guided

This V-guided conveyor has a rubber guide vulcanized to the underside of the belt. The frame and pulleys are then grooved / notched to provide a track for the rubber vulcanized belt. This “guided” system keeps the belt centered for side loading, long run and short but wide applications.

Note: Unit shown with optional siderails.

-

311 Medium Duty V-Guided

This V-guided conveyor has a rubber guide vulcanized to the underside of the belt. The frame and pulleys are then grooved/notched to provide a track for the rubber guided belt. This “guided” system keeps the belt centered for side loading, long run and short but wide applications.

-

321 Heavy Duty V-Guided

This V-guided conveyor has a rubber guide vulcanized to the underside of the belt. The frame and pulleys are then grooved/notched to provide a track for the rubber vulcanized belt. This “guided” system keeps the belt centered for side loading, long run and short but wide applications.

Note: Unit shown with optional side rails.

-

Welded Belt Conveyor

Stronger welded frame construction than bolt-together frame. Provides the most versatile means of handling a wide variety of products. Achieves higher speeds than other conveyor types. Many belt options for specific applications. Common applications include assembly, sorting, inspecting and transportation.

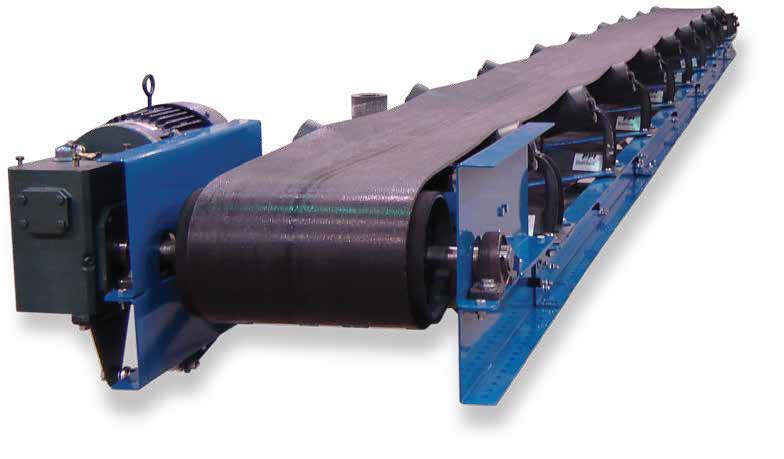

Roller Bed Conveyors

-

751 RB

Roach 751RB is the choice for heavier unit loads. The heavy duty roller bed construction makes model 751RB ideal for transporting heavy loads with low power requirements.

-

796 RB

Model 796RB, medium duty roller bed belt conveyor, is well suited for transporting unit loads with lesser horsepower requirements than slider bed belt conveyors.

-

640 Heavy Duty Belt Over Roller

Roller beds are used to convey heavy loads longer distances. (Pallets, wash machines, tires) Consider using a roller bed when your live load per foot exceeds 50#.

This heavy-duty, industrial-use conveyor is made with a roller bed carrying surface that reduces friction to increase load-moving capacity with lower power requirements.

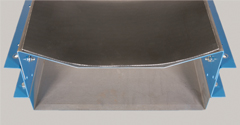

Trough Bed Conveyors

-

725 TB

725TB trough bed belt conveyor is ideal for handling chips, slugs, scrap wood, paper waste, boxes, packages and cartons. The troughed frame design offers integral guard rails for many trash conveyor applications.

-

Model 335 Trough Bed

Bed and belt are troughed for product containment, portable designs for flexibility and custom designs are available.

-

Trough Roller Bed Belt Conveyor

Endura-Veyor, Inc.’s Trough Belt Conveyors are proven performers in the recycling, wood, aggregate, foundry and waste to energy industries. Built for years of service with low maintenance, these conveyors feature time-tested, field-proven designs that last and last.

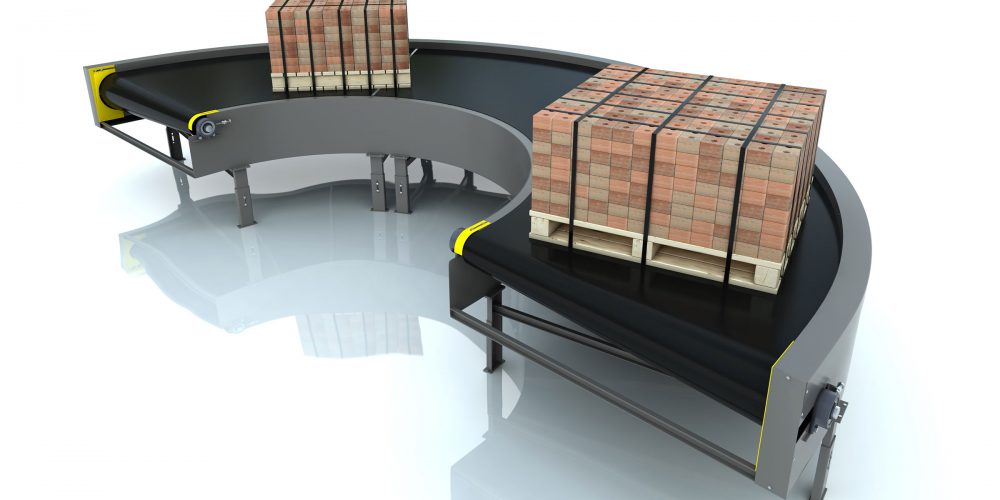

Curved Belt Conveyors

-

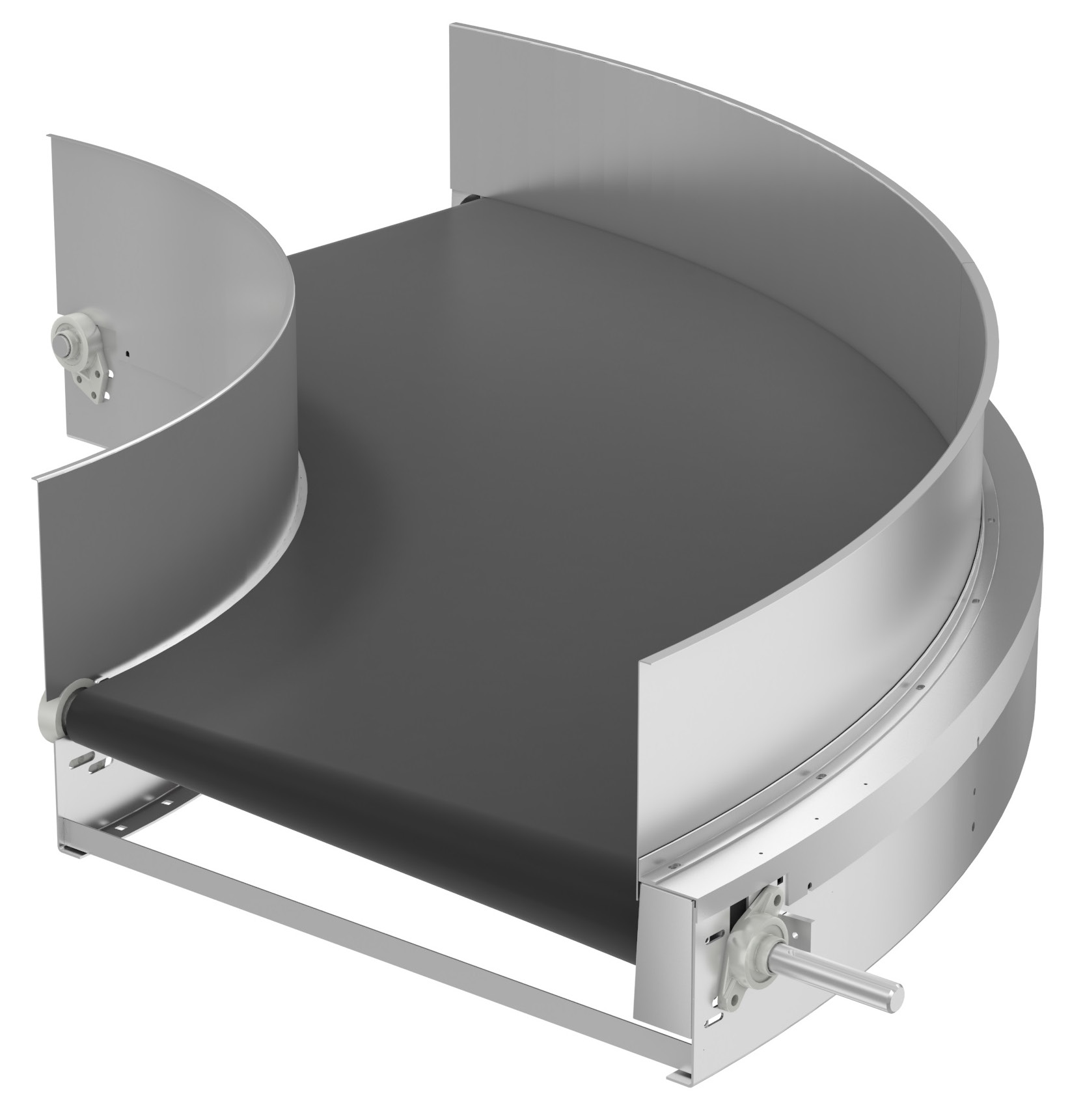

Jantec PTM Power Turn Conveyors

JanTec Power Turns are available in Standard, Heavy Duty (HD), and Small Pulley (SP) series, all available with a wide range of widths and radii to fit every application. Offering long life, and flexibility, as well as rugged construction, they may be ordered to handle loads from a few pounds to extremely heavy loads per turn. Drive pulleys are sized for the load. By driving through the entire width of the belt, not just outside the radius edge, heavy loads may be transported smoothly and efficiently. The guide system is designed with sealed ball bearings for long life in abrasive environments. No roller chains or sprockets are required. Speeds of up to 600 fpm at centerline can be provided.

-

Omni Belt Conveyor Curves

Belt Conveyor (BC) brings increased efficiency to applications such as assembly lines, sorting, inspection and transportation. Belt conveyors provide a versatile means of handling a wide variety of products from bulky boxes and bundled items to furniture, wood sheets, totes and packaged goods.

-

Portec / Interroll Belt Conveyor Curves

The Belt Curve has been specifically designed to provide trouble-free performance for many years in a variety of applications. The design accommodates many variations in width, arc and weight conveyance. The laced belt can be changed within a very short time and does not require the removal of the drive package. Our Belt Curve can operate in much higher and lower ambient temperatures than a friction-driven conveyor and reaches speeds of more than 600 ft/min. The combination of heavy duty equipment, durability and simple maintenance matched with quiet, high speed operation make Interroll the company of choice for airport professionals the world over.