Reciprocating vertical conveyors are an economical alternative for situations where the high rate capability of continuous flow vertical conveyors is not required. The load carrying platform on reciprocating vertical conveyors may itself be a powered roller bed, a belt conveyor or a chain conveyor. Loads ranging in weight from 10 pounds to 4,000 pounds may travel vertically up to 100 feet and speeds up to 120FPM.

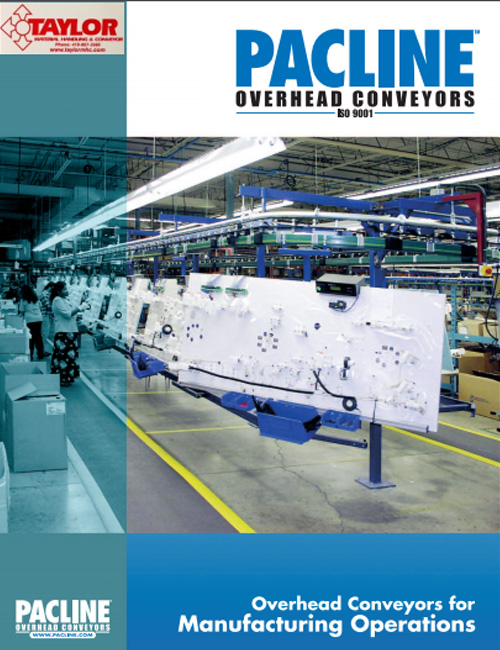

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Vertical Conveyors

Vertical Lifts with Conveyor Deck, Vertical Material Lifts , Vertical Tote, Box Drum Lifts

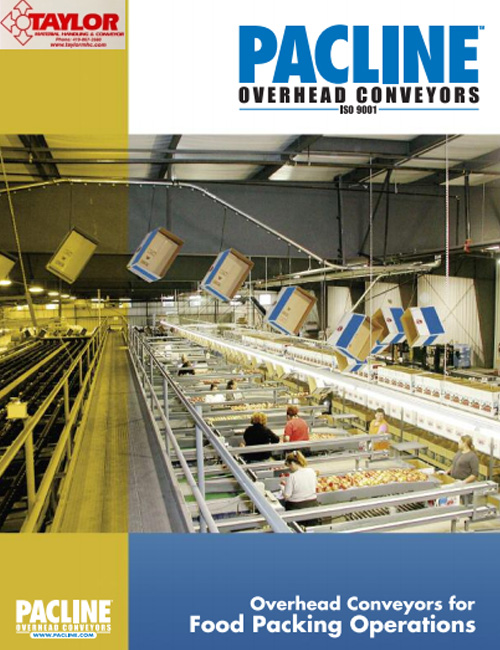

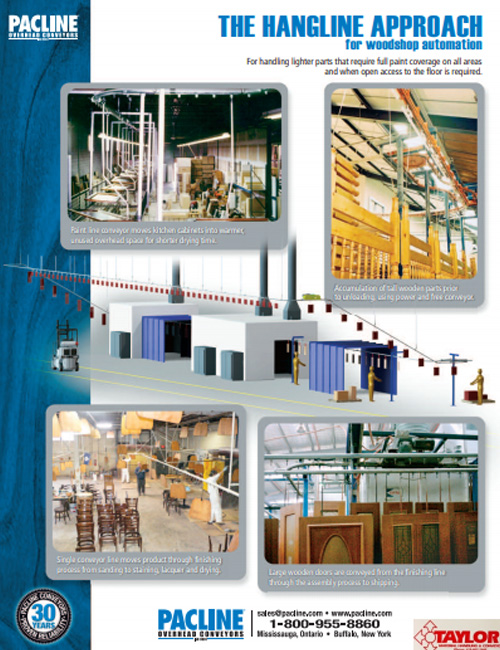

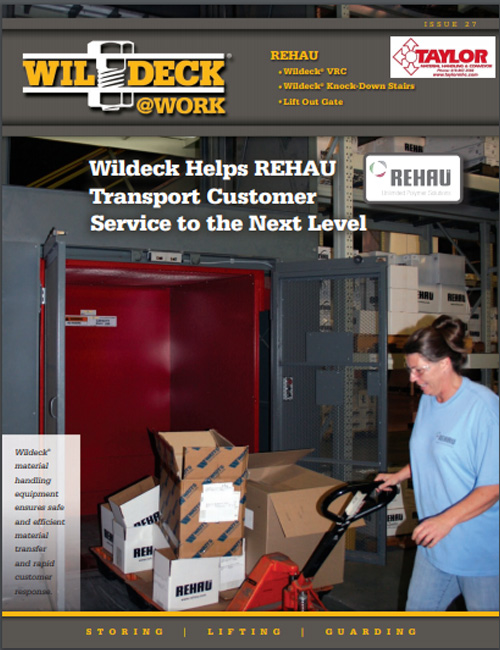

Manufacturing plants and storage or distribution/fulfillment facilities often need to move materials from one level to the next. Vertical conveyors and lifts are space-saving, durable, and cost-effective solutions to meet this conveying requirement. Let Taylor Material Handling & Conveyor guide you to the correct solution for your specific application. We are authorized Ambaflex, SpanTech, Wildeck, and Roach vertical conveyor and vertical lift dealers/distributors experienced in lifting applications for boxes, cartons, packages, totes, drums, containers, cases, pallets, bags, and many other items. Call us today for a no-obligation vertical conveyor quote.

-

Roach Model RVC - Vertical Conveyor

-

Roach Model CVC - Vertical Conveyor

Roach continuous vertical conveyors will carry loads weighing as much as 4,000 pounds for net lifts of up to 80 feet. Continuous running chain conveyor with evenly spaced, cyclical load platforms. Net lift heigh does not effect possible flow rate capability of these units as it does with reciprocating type vertical conveyors. Load platform remains perfectly level when unit load is being loaded, conveyed or discharged.

Vertical Tote, Box & Drum Lifts

-

Wildeck Automated Tote Lift

Wildeck’s Automated Tote Lift is a flexible and cost effective solution to increase the efficient vertical transfer of your goods. The Lift easily integrates into your conveyor system and features a modular design that delivers safe, reliable functionality. Whether it is a small mezzanine loading system with several “queue” sections, or a full blown conveyor system that needs loads moved up and out of the way – the Wildeck Automated Tote Lift is an ideal solution for your vertical movement needs.

-

Wildeck Modular Box Lift

With the push of a button the Wildeck Mechanical Modular Box Lift can quickly reduce the amount of manual trips up and down stairs. Efficiently and safely move parts and material packed in totes, boxes or carriers to another level. The modular design simplifies shipping and assembly. Electrical components are preassembled and prewired at the factory to reduce installation time.

-

Wildeck Hydraulic V-Lift

Wildeck’s next-generation hydraulic VRC (vertical reciprocating conveyor) incorporates industry leading technology and design including a robust hydraulic ram with large 2-½” diameter dual pistons that deliver a smoother and more positive lifting motion. Quality Wildeck construction and simplicity are clearly evident in the V-Lift and the single cylinder hydraulic system eliminates all moving hoses, cables, and chains. Fewer components means easy installation, reduced maintenance and longer service life.

Vertical Material Lifts

-

Wildeck Delta Lift

Also known as a freight or material lift, the Wildeck Delta Lift is a safe and reliable way to transfer your valuable material from level-to-level. The Delta Lift offers the lower cost of a hydraulic unit while Incorporating the many benefits of a mechanical lift…and more! Carriage platform of 5’ wide x 6’ deep x 7’ high with a lifting capacity up to 2,200#.

-

Wildeck 4x Lift

Step up to the power of a 4XLift from Wildeck, the leading manufacturer of safer, more reliable vertical lifts. The heavy duty four-post 4XLift includes, as standard, Wildeck’s patented AutoSenz Overload Detection System that continuously monitors motor current and stops the lift in its tracks should a jam occur. No other VRC (Vertical Reciprocating Conveyor) provides such a high level of protection for your material and the VRC itself. Two standard models are available in 15,000# and 30,000# capacity.

-

Wildeck Armor Car Carriage

The ArmorCar Carriage from Wildeck sets the standard for quality, reliability, and value for material handling lifts. The fully enclosed carriage provides safe transport of your material and prevents damage that can result from material or product falling off a standard carriage. It is available for new VRCs or can be retrofitted to upgrade existing Wildeck hydraulic or mechanical lifts.

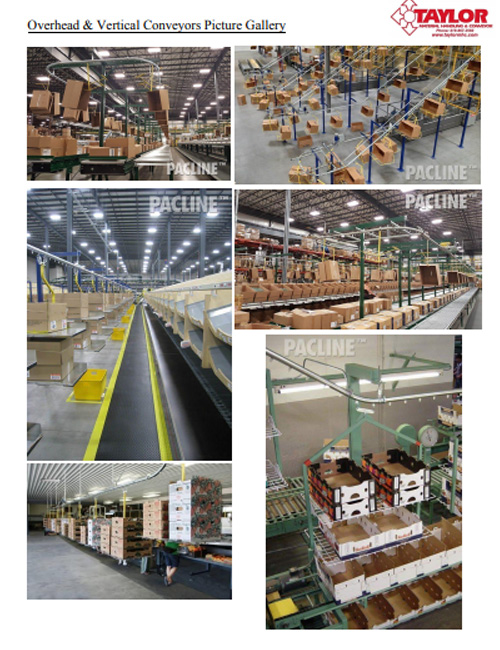

Integrated Vertical Lifts with Automated Conveyor Systems

-

Wildeck Xpresslift VRC

The XpressLift VRC has been specifically designed to efficiently integrate vertical lifting into automated conveyor systems. When combined with your conveyor system, the XpressLift VRC can help you achieve increased process efficiency through the automated vertical transfer of materials between your various conveyor levels.

-

Wildeck Flexloader

Flex your material lifting capabilities with the new FlexLoader Automated/Integrated VRC System from Wildeck, the leading manufacturer of safer, more reliable vertical lifts. The FlexLoader VRC (Vertical Reciprocating Conveyor) system utilizes automated flush-mounted conveyors with either a 2-Post or 4-Post VRC, and Wildeck Overhead Safety Gates at each level. This innovative design transforms a basic vertical lift into a safer, more efficient and more automated material lifting system that seamlessly connects all levels of your facility to make better use of the available space.

-

Wildeck Autosenz

Custom mechanical VRCs (vertical reciprocating conveyors) manufactured by Wildeck are now available with the advanced AutoSenz overload detection system which includes an easy-to-read graphical display interface and extensive system diagnostics that make the VRC much easier to use and understand.