Available in On-Off, changover, Star-delta, reversing, ammeter, voltmeter and step switch configurations. Bulletin 194L Control & Load Switches are designed for use as manual motor controllers and at motor disconnects. Padlockable handles available, optional enclosures and 1-6-pole versions.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Controls for Conveyors, Material Handling, PLCs, HMIs, Motor Control

Allen-Bradley Distributors

Our extensive control system installations are Allen-Bradley based, and include PLC-5, SLC-500, MicroLogix, FlexLogix, CompactLogix and ControlLogix. We offer a wide range of operator interfaces including but not limited to discrete operators, Allen-Bradley RSView products (PanelView, RSView and InView) including: DH-485, DH+, DeviceNet, ControlNet, EtherNet and ProfiBus.

Our Capabilities Include: Conceptual Design, Functional Specification, Drawing Package Generation, Field Commissioning, Procurement, System Testing, Customer Training, As-Built Documentation and Technical Support.

Control Systems play a critical role in space flight. Control Systems also play a critical role in small machines, conveyors and complete material handling systems.

Electrical Control Systems – Complete electrical control systems designed to suit our broad range of material handling equipment. Electrical control systems can include PLC programming with HMI’s (Human Interface Unit’s) or Fieldbus systems with Profinet. Electrical sensors include photo eyes, proximity switches and limit switches. Safety control circuits include light curtains, safety mats, pull cord cables and push button switches.

We provide a full service of electrical controls specializing in machine and material handling automation. Special control applications can include Bar Code Sortation, Print/Apply Label Machines, Motion Weighing and Counting of Product.

Field Installation – Our qualified installation crews are trained to provide quality, economical and on time installations. We can provide Non-Union or Union technicians to install the equipment we provide. We carefully select who we work with, ensuring quality customer service and results. No project is too small or too large. We are committed to providing quality installations.

Project Start-Up, Training & Ongoing Technical Support – Involvement with the project extends beyond the installation stage. Our team remains on-site to start-up the system and train customer personnel with operation & maintenance procedures. Ongoing technical support is also available as required to ensure system performance and production expectations.

Whether you need simple operator stations or complete control systems to support equipment for your plant equipment, Taylor Material Handling & Conveyor would like the opportunity to assist you with your control needs.

Taylor Material Handling & Conveyor can provide a custom designed electrical control system for you. Simply tell us what you want the system to do mechanically, and we will supply the electrical control system to operate it.

Electrical Controls can be provided three ways:

1.) Simple “Plug & Play” independent equipment controls consisting of an enclosure with main power disconnect, motor starters, variable speed controllers, operator push button stations, emergency stops, photo eyes and solenoid valves. Components can be pre-wired for “Plug & Play” field installation.

2.) Individual equipment controls consisting of combination starters with push buttons, emergency pull cord e-stops and photo eyes. These electrical controls can be mounted and wired to your specifications at your facility.

3.) Complete electrical control systems can include PLC programming with HMI’s (Human Interface Units) or fieldbus systems with Profinet. Electrical sensors include photo eyes, proximity switches and limit switches. Safety control circuits include light curtains, safety mats, pull cord cables and push button switches. This type of system is provided with our on-site start-up service with ongoing technical support.

Electrical Control Systems

Motor Control

-

Allen Bradley Motor Disconnects

-

Hubbell Disconnects

The switched Twist-Lock and Hubbellocl Enclosures integrate a receptacle and a switch to produce distinct advantages for the user. This enclosure replaces box, switch, cover and all in a compact design. Hubbell has developed the Switched Safety Enclosure because users want to be able to disconnect higher voltage devices confidently.

-

Square D Disconnects

The Square D brand heavy duty safety switch is designed to be tough, reliable and provide exceptional performance in the most grueling conditions: from commercial and institutional to industrial and manufacturing facilities. Square D F series safety switches provide significantly higher levels of mechanical endurance than NEMA KS-1 requires.

-

Manual Motor Starters

Manual motor starters are specifically designed for full voltage motor starting applications where remote push button control is not necessary. They are ideally suited for starting and protecting smaller motors frequently used for fans and blowers.

-

Reversing Drum Switch

The reversing drum switches find application wherever manual reversing control is desired. They are particularly suited for use on machine tools, woodworking machines, and similar equipment. Examples include lathes, milling machines, planers, grinders, shapers, and boring mills. Other possible applications include door operators, small hoists and conveyor belts.

-

Combination Starters

These full-voltage combination starters are designed to provide the disconnecting means, short-circuit protection (with suitable fuses), control and overload protection for three-phase squirrel-cage motors. All starters include a normally open auxiliary contract as standard.

-

AC Variable Speed Controllers

A variable speed frequency drive provides a soft start, gradually ramping ramping up a motor to operating speed. This gradual increase in current, lessens mechanical and electronic stress on the motor which reduces maintenance and repair costs and extends motor life.

-

KB Electronics AC Drives

Horsepower 1/8 to 5HP, Programmable 10 & 30 Input 115/230/460VAC, 50/60 Hz 30 Output 230/460VAC 200% Starting Torque Digital Display with LED Status Indicators (FDA Approved Finish) Easy to install and simple to operate. Provides overload protection, prevents motor burnout and eliminates nuisance tripping.

-

DC Variable Speed Controllers

DC Variable Speed Drive Packages include a DC motor, a DC variable speed controller, cord and plug.

-

PowerFlex 4M

PowerFlex 4M AC Drives are the smallest and most cost-effective members of the PowerFlex family of drives. Feed-through wiring and easy programming provide the flexibility to handle a broad range of applications.

-

PowerFlex 523

PowerFlex 523 AC Drives are cost-effective and ideal for standalone machines. These drives provide an innovative, modular design that supports fast and easy installation and configuration. In addition, they offer USB programming, application-specific configuration, and flexible mounting options.

-

PowerFlex 525

PowerFlex 525 AC Drives feature an innovative, modular design to support fast and easy installation and configuration. This next generation of compact drives offers embedded EtherNet/IP communications, USB programming, and standard safety features.

-

ArmorStart LT Distributed Motor Controller 290

ArmorStart LT 290 distributed motor controllers are economical, compact in size, and have a lightweight design. They are ideally suited for On-Machine conveyor and material handling applications. ArmorStart LT product line includes both full-voltage and reversing starters and an AC drive version.

– 290E ArmorStart LT ful voltage motor controller with EtherNet/IP communications. -

ArmorStart LT Distributed Motor Controller 291

ArmorStart LT 291 distributed motor controllers are economical, compact in size, and have a lightweight design. They are ideally suited for On-Machine conveyor and material handling applications. ArmorStart LT product line includes both full-voltage and reversing starters and an AC drive version.

– 291E ArmorStart LT full voltage reversing motor controller with EtherNet/IP communications.

-

ArmorStart LT Distributed Motor Controller 294

ArmorStart LT 294 distributed motor controllers are economical, compact in size and have a lightweight design. They are ideally suited for On-Machine conveyor and material handling applications. ArmorStart LT product line includes both full-voltage and reversing starters and an AC drive version.

– 294E ArmorStart LT variable frequency drive motor controller with EtherNet/IP communications.

Electrical Control Devices

-

Remote Start-Stop

– Push to Stop/Start

– Plastic NEMA 12 Enclosure

– Optional quick disconnect receptacle and cords.

– Horizontal or Vertical Mount -

Jog Push Button Switch

– Push button jog switch

– Plastic NEMA 12 enclosure

– Optional quick disconnect receptacle and cords.

– Horizontal or Vertical Mount -

Emergency Stop Pushbutton

– Plastic NEMA 12 Enclosure

– Optional quick disconnect receptacle and cords.

– Illuminated version optional

– Horizontal mounting bracket is standard. -

Foot Swichtes

The Hercules Anti-Trip models can be used on a wide variety of machinery including press brakes, material handling equipment, and man lifts. This rugged switch was designed to last even in the harshest environments. Step on reliable foot switch that you can trust each and every time.

-

Safety Limit Switches

Limit switch is a switch operated by the motion of a machine part or presense of an object. They are used for controlling machinery as part of a control system, as a safety interlocks, or to count objects passing a point. A limit switch is a electromechanical device that consists of an actuator mechanically linked to a set of contacts. When an object comes into contact with the actuator, the device operates the contacts to make or break an electrical connection.

-

Photo Eyes

Photoelectric Sensors operate by sensing a change in the amount of light that is either reflected or blocked by an object to be detected (target). The change of light could be the result of the presence or absence of the target or as the result in the change of the size, shape, reflectivity or color of a target.

-

Proximity Sensors

A proximity sensor is a sensor able to detect the presence of nearby objects without any physical contact. They often emit an electromagnetic radiation (infrared, for instance), and looks for changes in the field or return signal. The object being sensed is often referred to as the proximity sensor’s target. Different proximity sensor targets demand differenet sensors. The maximum distance that this sensor can detect is defined “nominal range.” Some sensors have adjustments of the nominal range or means to report a graduated detection distance.

-

Device Brackets

CIS Emergency StopsPhoto Eye Control Brackets are a widely used product in our industry. With the ability to adjust your photo eyes in hundreds of diffent ways leads to endless possiblities. With all the different types of photo eyes out there, you need all kinds of mounting brackets. Take a look, chances are we have what you need!

-

Solenoid Valves

Aluminum bar manifolds, featuring either threaded ports or integrated push-in connectors, together with modular stacking manifolds, allow the valves to be mounted conveniently in the required layout. Also available, is a pre-wired, plug-in modular manifold which can be ordered for use on a DIN rail system. SMC Z family of valves allows you to select from a comprehensive range of mounting brackets, electrical connectors, port adapaters, manifold accessories and serial transmission devices to provide the complete solution for your application

-

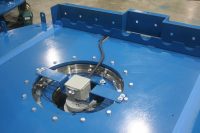

Turntable Slip Rings

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. A slip ring can be used in any electromechanical system that requires rotation while transmitting power or signals. It can improve mechanical performance, simplify system operation and eliminate damage-prone wire dangling from movable points. They can be used on any rotating object to transfer power, control circuits, or analog or digital signals.

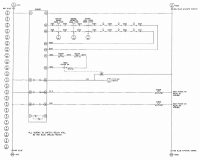

Electrical Control Systems

Electrical Control Systems Engineering is defined as the engineering discipline that applies control theory to design systems with desired behaviors. The practice uses sensors to measure the output performance of the device being controlled and those measurements can be used to give feedback to the input actuators that can make corrections toward desired performance. When a device is designed to perform without the need of human inputs for correction it is called automatic control.

-

Hoffman Mild Steel Enclosures

Hoffman mild steel enclosures consist of junction boxes, push button enclosures, wall mounted and floor mounted cabinets. Enclosures are available in many sizes and UL types including 1, 4 & 12. Enclosures are available in standard gray enamel or any custom color noted in our color chart.

-

Disconnect Switches

Control cabinet disconnect switches are available in many styles. Most common styles are the rotary and visible blade disconnect switches. Fusible or non-fusible versions can be provided upon application requirements.

-

Wiring Systems

Finger-safe power distribution terminal blocks to prevent accidental contact with live connectors – without the use of additional barriers or shields. Interface modules connect through pre-wired cables to digital and analog. Simplified design reduces bill of materials – one IFM module and cable replaces multiple terminal blocks, wires and terminations. Design flexibility – feed through, LED indication, fusing and interposing relay IFM’s are available to meet application variables.

-

Plug & Play Conveyor Controls

Individually Motor Driven Zero Pressure Accumulation Controls are available. Each accumulation zone is individually motor driven. The system includes all the controls and devices pre-mounted, wired and programmed for basic plug and play zero pressure indexing accumulation of product. Benefits include a wide range of applications, low cost of ownership and reduced time of installation. Controls are flexible to control chain driven live roller, drag chain, chain transfers and turntable units. Photo eyes are used to sense the product location.

-

Fieldbus System

The process automation system provides a single plant-wide control and information platform while the FOUNDATION Fieldbus standard provides the ability to distribute the control architecture throughout your facility. Combine these two powerful technologies to enable integrated, seamless distribution of data and the execution of process control with devices from multiple sources.

-

Panel Views

When you need an essential component, with added value, but with a reduced cost, look to the Allen-Bradley PanelView Component family of operator interfaces from Rockwell Automation. Leverage on the new features of PanelView Component, such as built-in programming software and integrated mounting clamps, to help improve productivity and maintenance, while enjoying the convenience and efficiencies of single-source buying.

-

Electrical Control Documentation Package

Our electrical control documentation packages include panel drawings, wiring schematics and PLC programming. Electrical device layouts can also be provided to assist field installation and start up.

Operator Interface Signaling

-

Panel Mount Alarms 855P

855P panel mount alarms allow local indication of the status of a machine or equipment while enhancing space efficiency with devices ready to be installed in a control panel. These devices include features that preserve the control panel integrity and reduce installation time.

-

Control Tower Stack Lights 854J (40mm) & 854K (60mm)

The Control Tower stack lights are designed to communicate status of different conditions alerting you to critical equipment and systems needs on plant floor. Available in a wide variety of light and sound functions, sizes, colors, voltages and mounting options help monitor some of your most challenging control panel and on-machine applications.

-

Industrial Horns 855H-855HM

855H audible devices include general purpose, high-performance, and recordable electronic horns that provide multi-stage, multi-tone voice messaging and volume control capabilities. The high-performance and recordable horns are available as stand-alone devices or with beacons attached.

Safety Control Equipment

-

Light Curtains

GuardShield safety light curtains offer an extraordinary robustness against high-mechanical impacts. The unique profile design is a perfect solution for heavy duty applications. An integrated laser feature allows for easy set up and a comfortable control of the alignment. With these features this product provides the highest reliability.

-

Laser Scanners

SafeZone safety laser scanners are Type 3 optoelectronic devices that use reflection of emitted infrared laser light to sense a person or object within a user-defined area. The Class 1 (eye safe) infrared laser scans a 190° or 270° angular area to create a two-dimensional detection field. Light reflected off an objector person in the field is processed by the SafeZone, which sends a stop signal to the machine.

-

Safety Mat Systems

When integrated to a suitable safety mat control, it detects a presence on the mat, a short circuit, or an open circuit. Under each of these conditions, the safety control issues a stop command. Multiple mats can be combined into one safety mat system with the use of joining trim.

-

Guard Interlocks

Featuring RFID technology for coding, inductive technology for sensing and combining a large sensing range with optimal operation and a generous tolerance to misalignment, SensaGuard switches offer a cost-effective solution that is ideally suited to a wide range of safety applications and is intended for use with all types of guard doors.

-

Emergency Pull Cords

For machinery such as conveyors, it is often more convenient and effective to use a cable pull device along the hazard area (as shown in the figure above) as the emergency stop device. These devices use a steel cable connected to latching pull switches so that pulling on the cable in any direction along its length will trip the switch.