138VP accumulates goods safely and with minimum back pressure. Reversible, it can transport loads up to 100 lbs./ft. with as little as 2-1/2% back pressure. Ideally, packages of uniform weight can be accumulated temporarily using pneumatic package stops.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

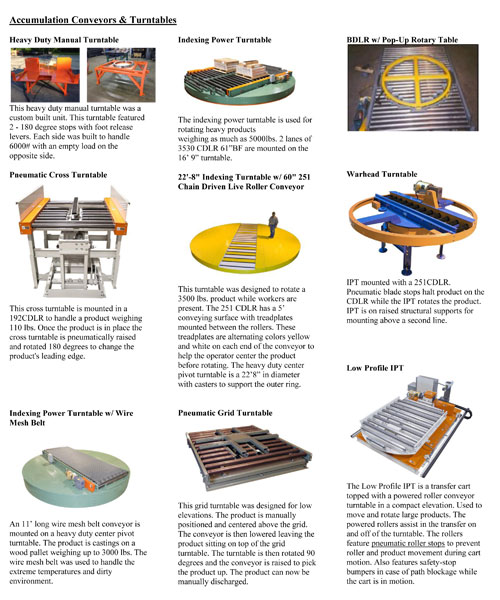

Accumulation Conveyors & Turntables

Roach Conveyor Distributors

Taylor Material Handling & Conveyor is an authorized Roach accumulation conveyor distributor. These conveyors are designed to allow collection of material along production line. They allow for the buffer of work between processes as production rates can change from the rate of consumption.

ACCUMULATION CONVEYORS

-

138 VP

-

196 VP

Model 196VP, variable pressure accumulator, conveys loads up to 125 lbs./ft. with as little as 2-1/2% back pressure. With reversible center drive, this unit accumulates goods safely with minimum back pressure. Ideally, packages of uniform weight can be temporarily accumulated by combining Roach pneumatic package stops.

-

196 ZPA

Roach 196ZPA safely accumulates packages with zero back pressure utilizing zone singulation operation. Loads up to 125 lbs./ft. may be effectively handled with its unique design. This conveyor features NO minimum weight limitations. Sensor rollers are utilized to accumulate products with previously difficult minimal weight restrictions.

-

SZ 196 ZPA

Roach SZ196ZPA Smart ZONE® safely accumulates packages with zero back pressure utilizing zone singulation operation. Loads up to 125 lbs./ft. may be effectively handled with its unique design. This conveyor features NO minimum weight limitations. Roach Smart ZONE® replaces sensor rollers with photo electric sensors to accumulate products with previously difficult minimal weight restrictions and is easy to install.

-

SZ 251 ZPA

Model SZ251ZPA SMART ZONE® is a heavy duty zero pressure accumulator, designed to accumulate heavy products, containers and pallets in 5’ zones. The Roach design incorporates photo electric sensors-instead of sensor rollers, eliminating many common problems associated with conveying wooden pallets. Products do not touch during accumulation and are singulated individually off of conveyor. Heavy loads weighing up to 3000 lbs. may be safely accumulated with Roach SMART ZONE®.

-

SZA 192 CDA

SZA192CDA SMART ZONE® is a single drive medium duty roll-to-roll chain driven zero pressure accumulator with air clutch operated zones, designed to safely accumulate medium duty loads in 5’ zones. Roach SMART ZONE®incorporates photo electric sensors to detect product loads instead of sensor rollers-which eliminates many problems associated with sensor rollers. Products do not touch during accumulation and are singulated individually off of conveyor. SMART ZONE® is easy to install and simple to maintain.

-

SZD 192 CDA

SZD192CDA SMART ZONE® is a multiple drive medium duty roll-to-roll chain driven zero pressure accumulator, designed to safely accumulate medium duty loads in 5’ zones. Roach SMART ZONE®incorporates photo electric sensors to detect product loads instead of sensor rollers-which eliminates many problems associated with sensor rollers. Products do not touch during accumulation and are singulated individually off of conveyor. SMART ZONE® is easy to install and simple to maintain.

-

SZA 251 CDA

SZA251CDA SMART ZONE® is a single drive heavy duty roll-to-roll chain driven zero pressure accumulator with air clutch operated zones, designed to safely accumulate heavy products such as castings, drums, containers and heavy pallet loads in 5’ zones. The Roach design incorporates photo electric sensors-instead of sensor rollers-which eliminates many of the problems associated with conveying wooden pallets. Products do not touch during accumulation and are singulated individually off of conveyor. SMART ZONE® is easy to install and simple to maintain.

-

SZD 251 CDA

SZD251CDA SMART ZONE® is a multiple drive heavy duty roll-to-roll chain driven zero pressure accumulator, designed to safely accumulate heavy products such as castings, drums, containers and heavy pallet loads in 5’ zones. The Roach design incorporates photo electric sensors– instead of sensor rollers–which eliminates many of the problems associated with conveying wooden pallets. Products do not touch during accumulation and are singulated individually off of conveyor. SMART ZONE® is easy to install and simple to maintain.

-

SZ 796 LSZ

SZ796LSZ SMART ZONE® quietly accumulates a wide variety of product sizes and features NO minimum weight limitations. SMART ZONE® eliminates sensor rollers and replaces with photo electric sensors to accumulate products with previously difficult minimal weight restrictions. This zero pressure line shaft driven accumulator is ideal for numerous light to medium duty applications since curves, spurs and other modules may be driven by a SINGLE drive.

-

796 LSZ

Model 796 LSZ is one of the most popular accumulators in the unit handling industry. This zero pressure line shaft driven accumulator is ideal for numerous light to medium duty applications. Curves, spurs and other line shaft modules may be driven by a SINGLE drive.

TURNTABLES

-

Indexing powered turntables convey heavy unit loads in numerous applications. A heavy duty chain driven live roller may be mounted on turntable platform and rotated to orient product at specified intervals allowing operator to perform a variety of tasks.

-

Typically used in sorting applications and

systems with a 180 degree turn. These units can turn products 180 degrees in spaces traditional units can’t. -

This unit is used in applications to accumulate or sort products to orientate them allowing the operator to perform a variety of tasks. The deck can be made of carbon or stainless steel.

-

Unlike other conveyor manufacturers, Alba provides pre-engineered turntables. Our standard turntable diameters range in various increments from 72″ to 82″. Depending on your load size and weight requirements, our standard effective widths range from 44″ to 60″.

-

Manual Turntables are used for loading and unloading pallets and containers, as well as improving the ergonomics of workstations.

-

Powered Turntables are useful for providing directional change in your conveying line. A section of conveyor can be attached to the table surface and is then rotated to the desired position for product flow in a system.