Model 1000-S is designed for straight running applications. This unit is capable of supporting various styles of plastic chains and metal chains. This conveyor is used to carry lighter weight products common in bottling operations, dairies and pharmaceutical plants.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Table Top Chain Conveyors

Dorner, New London, SpanTech Distributors, Plastic Chain, Metal, Modular, Curved, Straight

Table top chain conveyors are solutions for conveying that requires multiple curves and elevation changes. We are authorized Dorner, SpanTech, and New London conveyor distributors, the leading brands in the industry. Table top conveyors are in use in many industries such as bottling, beverage, medical, pharmaceutical, consumer products, and food processing. Let Taylor Material Handling & Conveyor guide you to the correct solution for your specific table top chain application. Call or email with any questions today.

-

Model 1000-S

-

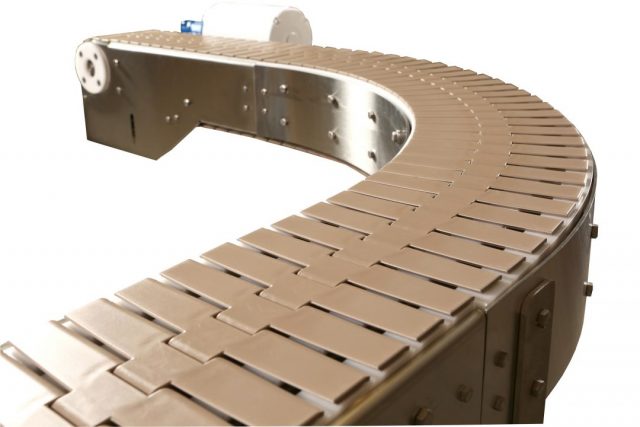

Model 1000-C

Model 1000-C is used when the application requires right hand or left hand curves. This unit is capable of supporting various styles of plastic and metal chains. This conveyor is used to carry lighter weight products common in bottling operations, dairies and pharmaceutical plants.

-

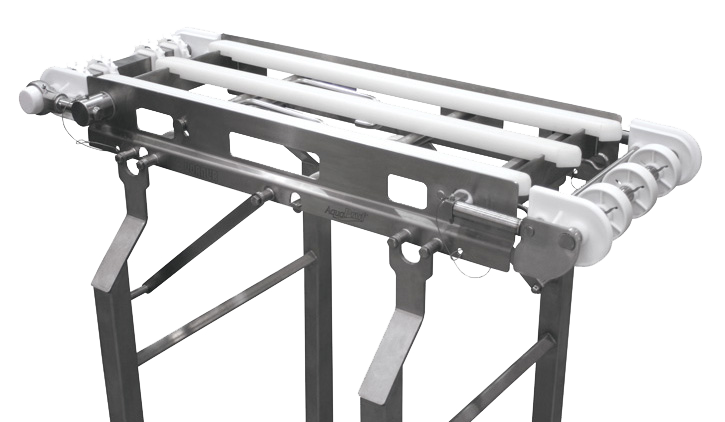

Spantech MiniLink

This conveyor utilizes a single plastic chain link, running on a welded stainless steel I-beam. Like all Spantech conveyors, MiniLink has no cumbersome catenary which must be re-fed back on track. Because the MiniLink rail may be shaped to create both vertical and horizontal curves, combinations of inclines and horizontal turns are possible within a single conveyor.

7x Series Conveyors (Sanitary)

-

AquaGard 7100 Series Conveyors

Industry ready stainless steel flexible chain conveyor.

-

AquaGard 7200 & 7300 Series Conveyors

Sanitary conveyor rated for low pressure wash down with soap and water cleaners. Low profile, stainless steel sanitary conveyor rated for high pressure washdowns with caustic cleaners.

-

AquaGard 7350 Series Conveyors

The 7350 Conveyor is built for maximum flexibility with straight, curve and z-frame module options.

-

AquaGard 7360 Series Conveyors

Suitable for wipe-down and occasional pressurized liquid spray cleaning up to 100 psi.

-

AquaPruf 7400 Series Conveyors

Straight, curved, and Z-frame models available. Curved conveyors can have up to 2 curves with curves from 15º to 180º (with up to 240º total).

-

AquaPruf 7400 Ultimate Series Conveyors

Engineered for Fast & Effective Sanitation in the most demanding environments. Optional clean in place module cleans inner and outer surfaces of belt. Cleaning channels allow for complete sanitation and access to spindles.

-

AquaPruf 7600 Series Conveyors

The open frame design allows for easy conveyor cleaning. Designed to transport food & pharmaceutical product with confidence. Available in a variety of belt types and materials including cleated belts.

-

AquaPruf 7600 Ultimate Series Conveyors

Frame is designed with no horizontal surfaces for optimum cleaning. Solid UHMW wear strips are easily lifted out of the frame without tools to minimize cleaning time. The tool-less tip up pulley allows conveyor end to be lifted easily for quick access to inside.

-

AquaPruf 7600 Series VBT Conveyors

Belt design features staggered sidewalls to increase pocket capacity and reduce product loss. The clean through side wall design improves clean-ability, reduces cleaning time and water usage.

- +Product Literature

- +Application Photos/Videos