- Automotive

- Bottling & Canning

- Material Handing

- Packaging

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Conveyor Components

Conveyor Belts, Drive Motors, Rollers, Reducers, Sprockets, Gears, Pulleys

Motors

- AC Unit Handling & Conveyor Motors

- AC Inverter Duty Motors

- AC Brake Motors

- AC Servo Motors

- DC Motors – Permanent Magnet

- Gearmotors

- Wash-down Duty Products

- AC Drives

- DC Drives

Reducers

- Dodge Tigear-2 Reducers

- Dodge Quantis Combination Reducers

- SEW Gearmotors

Sprockets, Gears, Bushings & Couplings

- Roller Chain Sprockets

- Roller Chains & Specialty Chains

- Conveyor Chains with Attachments & Sprockets

- Gates Poly Chain Sprockets

- Gates Poly Chain Drive Belts

- Bushings

- Couplings

- Gears

- Torque Limiters

Bronze Bushings, Mounted Bearings & Take-Up Bearings/Frames

- Bronze Bushings

- Set Screw Ball Bearings

- Take-Up Frames & Bearings

- Shaft Mounted Cam Follower Bearings

- Guide Wheels

- Washdown Duty Mounted Bearings

Pulleys

- Conveyor Pulleys

Conveyor Belting

- Types of Belting

- Lacing Styles

- Belt Options

- Belting By Industry

Plastic Modular Belts & Table Top Chain

- HabasitLINK Plastic Modular Belts

- Intralox Belting

- HabaCHAIN Slat & Conveyor Chains

Timing & Hinged Steel Belts

- Hinged Steel Belting

- HabaSYNC Timing Belts

- BrecoFlex Timing Belt Applications

Gravity Rollers

- Standard Rollers

- Specialty Metal Rollers

- Plastic Rollers

- Plastic Idler Rollers

- Stainless Steel Rollers

- Trough Rollers

Powered Rollers

- Poly “V” Driven Rollers

- CDLR Rollers

Roller Coatings, Sleeves & Bearings

- Roller Coatings & Sleeves

- Metal Roller Bearings

- Plastic Roller Components

Belts

Drive Components

Motors

-

AC Unit Handling & Conveyor Motors

- TEFC 1/6 – 30 HP

- 115-230VAC/1PH

- 230-460VAC/3PH/60Hz

-

AC Inverter Duty Motors

- Super E Premium Efficient Motors

- Energy saving applications where continuous or frequent duty is required. Suitable for use with inverter drives for variable torue and 20:1 constant torque.

- TEFC 1 HP-10 HP

- 230-460VAC/3PH/60Hz

-

AC Brake Motors

- Unit and baggage handling, conveyors, packaging equipment, machine tools, hoists, elevators and door operators.

- TEFC 1/2 HP- 10 HP

- 230-460VAC/3PH/60Hz

-

AC Servo Motors

- Allen Bradley Kinetix VP Servo Motors connect to and operate with Kinetix 5500 Servo Drives, supporting integrated motion on EtherNet/IP.

- Based on proven MP technology for dynamic performance, these motors help to increase reliability and leverage high volume production.

- Typical applications include: automated assembly, automated inspection, material handling, packaging and pharmaceutical.

-

DC Motors - Permanent Magnet

- Applications consist of conveyors, mixers and packaging machinery.

- General purpose motors 1/50 HP to 5 HP

- NEMA or IEC mounting available

- 90 or 180 VDC for 1PH Control

-

Gearmotors

- AC & DC Gearmotors

- Right Angle Gearmotors

- Parallel Shaft Gearmotors

-

Washdown Duty Products

- Baldor’s wash-down duty, paint-free wash-down and stainless wash-down are suited for applications requiring high-pressure cleaning with caustic solution. These choices allow you to select the right motor for the amount of protection required for the specific application.

- The widest variety of wash-down duty motors available from stock. Motors may be selected with the required voltage, horsepower, speed and mounting for the application. Plus, Baldor offers your choice of permanent magnet DC and Servo motors with wash-down duty construction.

-

AC Drives

- General Purpose Drives: 0.75

- 550HP

- Encoderless and closed-loop vector motor control

- UL NEMA 1 and NEMA 2 enclosures

- Machinery and Micro Drives: 0.25

- 30HP

- 115-230VAC/1PH

- 230-460VAC/3PH

- V/Hz and Sensorless Vector motor control

- NEMA Open and NEMA 4X enclosures.

-

DC Drives

- 1/100 – 5HP, Permanent magnet or shunt wound DC motor

- 115 VAC & 230 VAC, Single Phase Input

- 90 VDC & 180 VDC, armature output

- Chassis mount, NEMA 1, or NEMA 4X Enclosures

Reducers

-

Dodge Tigear-2 Reducers

- Tigear-2 is the only complete line of single-reduction, right-angle worm speed reducers specifically engineered with advanced sealing and bushing system technology that can actually lower your total cost of ownership.

- TIGEAR-2 is offered in 10 sizes covering center distances from 1.33″ to 4.75″. It has a 30% increase on average output torque (up to 6,800 in-lbs.), and because of the consistent torque capacity increments between case sizes, equipment designers can optimize reducer size selections for cost, performance, and life.

-

Dodge Quantis Combination Reducers

- The Quantis Right Angle Helical Bevel features a helical-bevel-helical gear train that offers cost effective, high and low speed solutions with efficiency ratings up to 94%.

- Quantis RHB is available in eight sizes, RHB38-RHB168.

- Ratios range from 4.83:1 to 307:1.

- Input horse powers start at 1/4 HP up to 75 HP.

-

SEW Gearmotors

- Input horsepower capabilities range from 1/4 hp to 75 hp.

- Design is entirely interchangeable with SEW-Eurodrive products commonly found in food and packaging applications.

- One-piece case construction optimizes overhung loads and minimizes joints to remove potential leak paths.

- All ground gearing increases efficiency and decreases noise.

- Options including integral motors (for limited space), clamp-collar construction or three-piece coupled construction increase flexibility.

Sprockets, Gears, Bushings & Couplings

-

Roller Chain Sprockes

- Shear Pin

- Solid & Split Detachable Hubs

- #40 Chain

- #50 Chain

- #60 Chain

- #80 Chain

- #100 Chain

-

Roller Chains & Specialty Chains

Roller chain size can usually be identified by the following measurements:

- the pitch, this is the distance between the centers of the pins.

- the inside width, this is the distance between the innermost sideplates.

- the roller diameter, this is the diameter of the roller.

-

Conveyor Chains with Attachments & Sprockets

- Double Pitch Chains

- Chain Attachments for Specialty Conveyors

- Double Pitch Sprockets

-

Gates Poly Chain Sprockets

- Poly Chain GT2 belt drive systems feature a new line of sprockets that have been redesigned to carry the new increased belt power ratings. These new sprockets utilize the Taper-Lock bushing system that has been tested and proven in industry for many years. This allows easy sprocket installation and removal and keeps the hubs narrow so the length-thru-bore dimension is less than ever before. Now, Poly Chain GT2 sprockets will fit on those applications with short shafts, with room to spare.

-

Gates Poly Chain Drive Belts

- Synchronous belt drives are being used more extensively than ever for the transfer of power from one shaft to another, multiplication of torque, speed reduction or increase, and synchronization of shaft operations. The powerful Poly Chain GT2 polyurethane belt drive system will outperform roller chain drives and any rubber belt drive system on the market today, delivering the lowest cost belt drive system available for low speed, high torque applications.

-

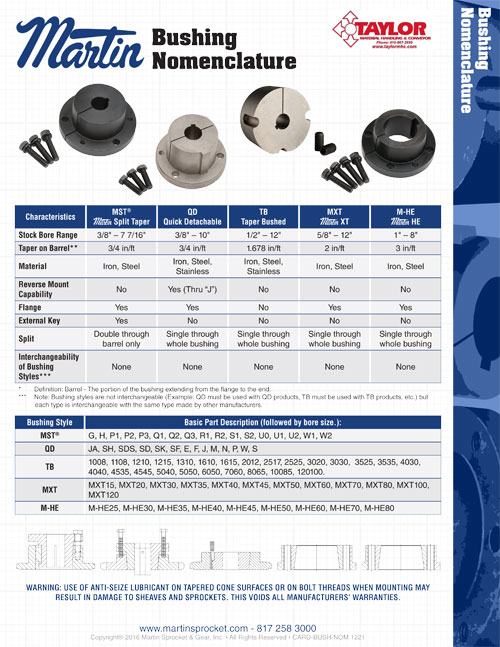

Bushings

Bushings are available in various styles. Standard items such as QD & taper locks come in sizes of 3/8″ dia. to 12″ dia. bores. Weld on hubs range from 2 1/4″ dia. to 19 1/2″ dia.

-

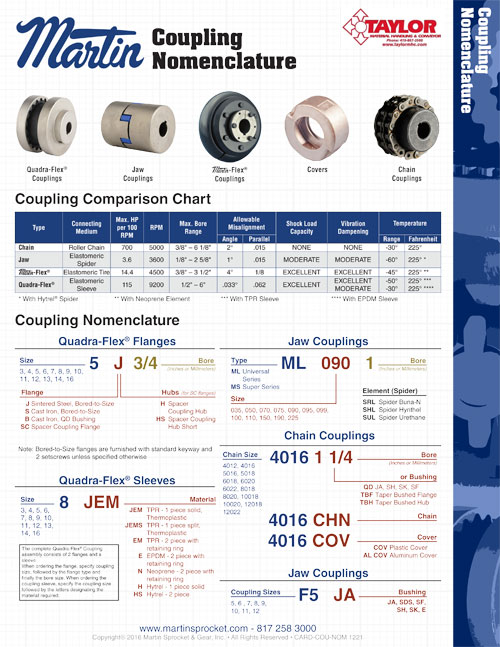

Couplings

Martin-Flex flexible couplings smoothly transmit power while compensating for shaft misalignment to 4°, parallel misalignment to 1/8″ and end float to 5/16″. The two piece flange design provides quick and easy installation and the elastomeric element absorbs shock and tensional vibration through a wide temperature range.

-

Gears

Martin stock spur gears are available in five different styles. Steel gears are furnished in plain style and plain style with hub. Cast gears are furnished, plain with hub, web with lightening holes and spoke. Cast gears are machined on all operating surfaces. Martin cast gears are cast with larger hub to provide extra strength and to allow for larger boxes.

-

Torque Limiters

A torque limiter is an automatic device that protects mechanical equipment, or its work, from damage by mechanical overload. A torque limiter may limit the torque by slipping (as in a friction plate slip-clutch), or uncouple the load entirely (as in a shear pin).

Bronze Bushings, Mounted Bearings & Take-Up Bearings/Frames

-

Bronze Bushings

BOST-BRONZ is Boston Gear’s all purpose, oil impregnated porous bronze bearing material. It is manufactured of highest purity metal powders by the powder metallurgy process. BOST-BRONZ bearings can be used on any application where the load-carrying capacity required falls within the capabilities of the material. BOST-BRONZ bearings operate efficiently under heavy loads at low speeds. Because these bearings are supplied with oil impregnation, the original oil content provides long-lasting lubrication. For even longer life requirements, many applications incorporate impregnated felts or reservoir techniques about the bearing.

-

Set Screw Ball Bearings

Four types: normal duty SC, medium duty SCM, intermediate duty VSC, and light duty SL.

-

Take-up frames & Bearings

ake-Up frames are available for narrow slot and wide slot bearings. Frames have travel from 1 1/2″ to 30″. Bearings range from 1/2″ dia. to 3″ dia.

-

Shaft Mounted Cam Follower Bearings

Shaft mounted cam follower bearings are available from 1″ dia. to 7″ dia. These products are lubed for life, have high load capacities at high speeds and longer service life. Shaft diameters range from 7/16″ dia. to 4 1/4″ dia.

-

Guide Wheels

Yoke rollers are available in similar sizes as shaft mounted except they are mounted on a pin for use in yoke type applications for greater shock resistance. Yoke rollers should be clamped axially or mounted with close fitting side rails to prevent disassembly.

-

Washdown Duty Mounted Bearings

The Dodge E-Z Kleen and Ultra Kleen bearings for the food and beverage industry offer an array of features that provide extended life in these challenging conditions. Dodge has the only bearings in the industry to offer a patented triple lip-seal with a rubberized flinger called the QuadGuard sealing system. These units also include an exclusive ball retainer called the Maxlife cage that helps retain lubrication and prevents washout in wet environments.

Pulleys

Plastic Modular Belts & Table Top Chain

-

HabasitLINK Modular Belts

Habasit plastic modular belts are assembled in a brick lay pattern. This feature allows the construction of virtually any width and length. Our custom-made belts are available with flights and side guards as an integral part of the belt, and are secured with full-width plastic hinge rods.

-

Intralox Belts

Intralox belts are made of plastic modules and are assembled in an interlocked, bricklayed pattern with full-length hinge rods—an inherently strong design. Driven and tracked by plastic sprockets, Intralox belts have the qualities that plant operators and designers look for: corrosion resistance, positive drives, high strength, low friction, abrasion resistance, and the ability to be built to almost any width and length, with a variety of flights, side guards, and other accessories.

-

HabaCHAIN Slat & Conveyor Chains

Designed, produced, and serviced by the worldwide leader in belting, the HabaCHAIN range offers top-class innovation and quality combined with excellent reliability and cost-efficiency.

HabaCHAIN products are available in both straight-running and radius/side-flexing versions, and run on most systems and sprockets on the market today. They are fully compatible with industry standards, making them ideal for retrofitting.

Timing & Hinged Steel Belting

-

Hinged Steel Belt

The conventional belt’s aprons are recessed below the hinge loops of the belt. This design results in a raised surface at the point where the belt loops are mated and allows a taller cleat. This radial surface also acts as ashort cleat that helps carry product up inclines. Conventional belts are used for most applications.

-

HabaSYNC

HabaSYNC timing belts support conveying and linear movement applications where optimum performance requires precise product placement and component positioning. – HabaSYNC belts are generally used in applications where exact product placement and precise component positioning is required. Synchronization is achieved by meshing the belt teeth into a matching similar-pitch pulley. Our timing belts are available in imperial and metric pitches.

-

BrecoFlex Timing Belt Applications

Conveyor Rollers & Bearings

Taylor Material Handling & Conveyor offers a full line of metal and plastic rollers and conveyor components. Materials include aluminum, carbon steel, stainless and galvanized steel. Plastic rollers are made from specially formulated Hi-Impact PVC with UV stabilizers. Urethane, PVC, UHMW and High Density Polyethylene covers with steel reinforcement are available for specialized applications.

Gravity Rollers

-

Standard Rollers

Roller tube diameters ranging from 1″ to 8″ Roller tubes are available in the following materials:

- Mild (low carbon) steel

- Galvanized steel

- Stainless steel

- Aluminum

- PVC (pipe)

- Industrial steel pipe

-

Specialty Metal Rollers

Specialty metal rollers are available in a wide range of bearings, tubes and shaft combinations. Typical applications include: Food & Beverage, Agriculture, Chemical, Unit Handling, Bulk Handling Distribution & Manufacturing. We specialize in all types of conveyor rollers for gravity and powered applications. We can also manufacture custom rollers to your specifications.

-

Plastic Rollers

Plastic rollers are available in a wide range of bearings, tube and shaft combinations. Plastic rollers are ideal for light duty gravity applications, humid, corrosive or wet environments. Typical applications include; food processing, chemical or acidic environments, battery handling and package handling.

-

Plastic Idler Rollers

Plastic idler rollers are available in through hole, blind hole or grading and inspection configurations. Tubing is available in standard or “Hi-Impact” formulation. The “Hi-Impact” material has UV stabilizers and additional impact modifiers. Tube diameters and wall thicknesses are available for virtually every type of application. All materials are FDA approved. Stainless steel bushing adapters and cap screws are also available to complete your roller requirements.

-

Stainless Steel Rollers

All stainless steel rollers and components are intended for use in frequent wash down, high corrosive and food processing applications.

- Manufactured with 304 stainless steel, mill finish materials.

- Wash down rated

- Stainless steel sprockets and fasteners

- FDA/USDA approved materials

- Continuous MIG welds

-

Trough Rollers

Trough roll units are available in both 2 roll (V-trough) and 3 roll configurations. They are designed for the continuous bulk conveying of food products, feed, grain, fertilizer, chemicals, corrosive substances and other materials. ideals for replacement of fluming, hinge wall belting and conveyors with side boards. These units are rated for light to moderate loads with speeds up to 300 FPM.

Powered Rollers

-

Poly V Driven Rollers

Poly “V” driven rollers are available in 1.9″ dia. and 2 1/2″ dia. Rollers can be made from steel or stainless steel and can be provided with 2 ribs up to 8 ribs for higher capacities.

-

CDLR Rollers

Chain Driven Live Rollers are available from 1.9″ dia. up to 5″ dia. Roller capacities range from 252# up to 3750#. Rollers can be built from stainless steel and coated with polyurethane for non-marking positive drive situations.

Roller Coatings, Sleeves & Bearings

-

Roller Coatings & Sleeves

Rollers available with urethane and vinyl sleeves. Coatings available in cast urethane, mill-able urethane, black rubber, food grade and other materials based on the application.

-

Metal Roller Bearings

Metal Roller Bearings are designed to manage heavy radial loads through expertly designed critical dimensions such as roller and raceway diameter and contact geometry. Available in one-, two-, four-row and full complement configurations.

-

Plastic Roller Components

Bushings, or Roll End Bearings, can be used in place of traditional ball bearings in rollers. In applications with speeds less than 150 FPM they offer many advantages.

- No lubrication to be washed away or dry out. Applications Consist of:

- Sanitary and food, high temperature, low temperature and corrosive environments.

- +Product Literature

- +Application Photos/Videos

-

Baldor General Catalog

-

Bushing Nomenclature

-

Coupling Nomenclature

-

Gear Engineering Data

-

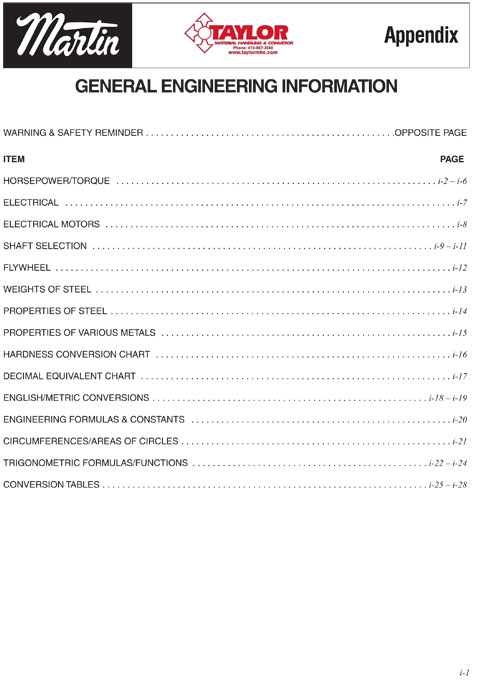

General Engineering Information

-

Roach Glossary & Terms

-

Roach Technical Info

-

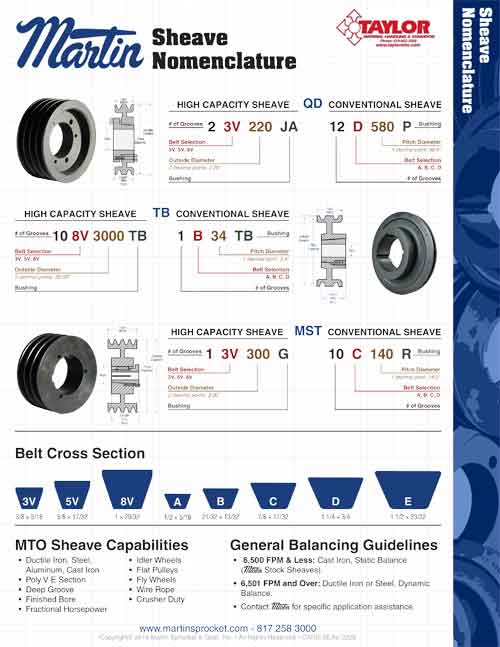

Sheave Nomenclature

-

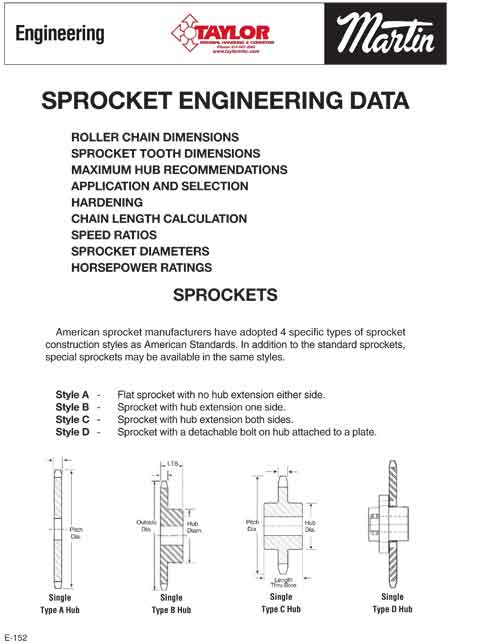

Sprocket Engineering Data

-

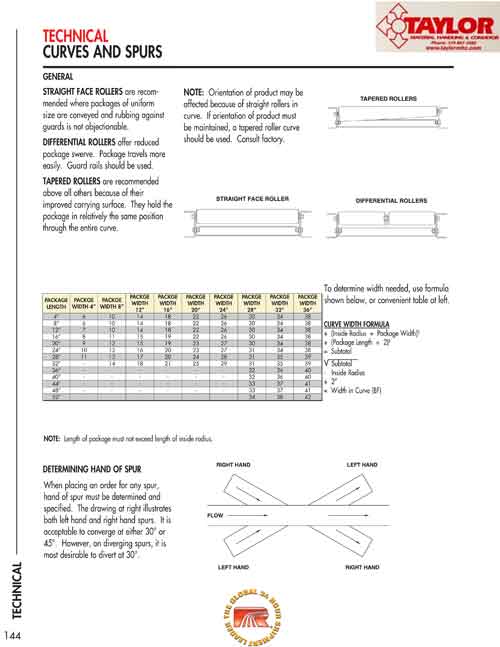

Technical Curves & Spurs

-

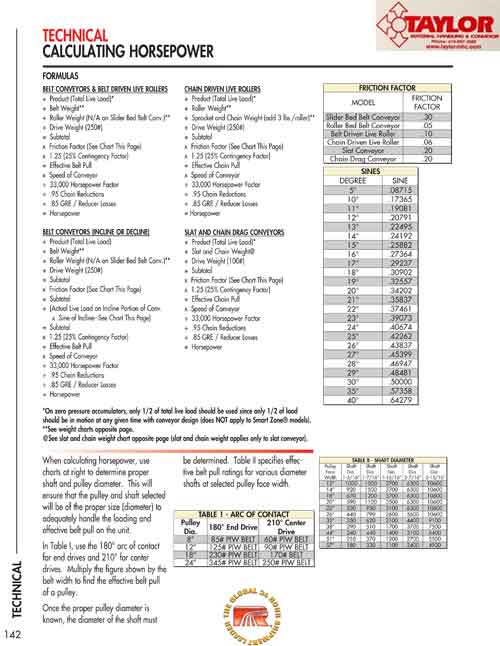

Technical Horsepower Calculation

-

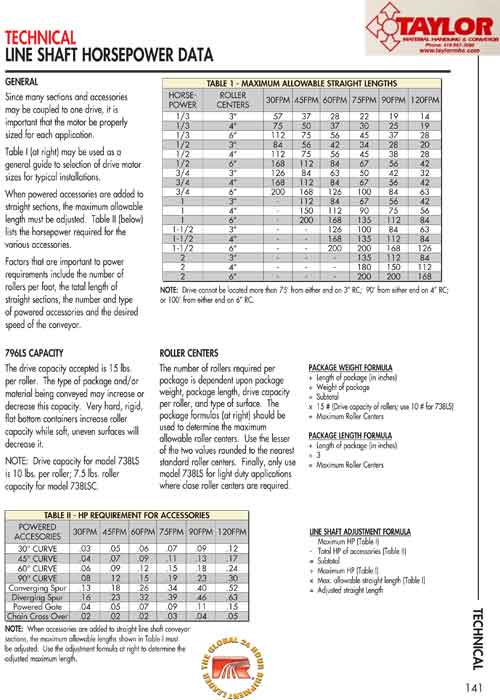

Technical Line Shaft Horsepower Data

-

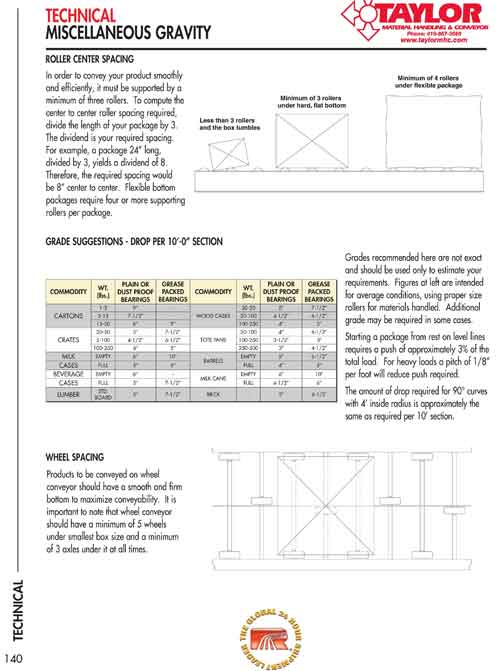

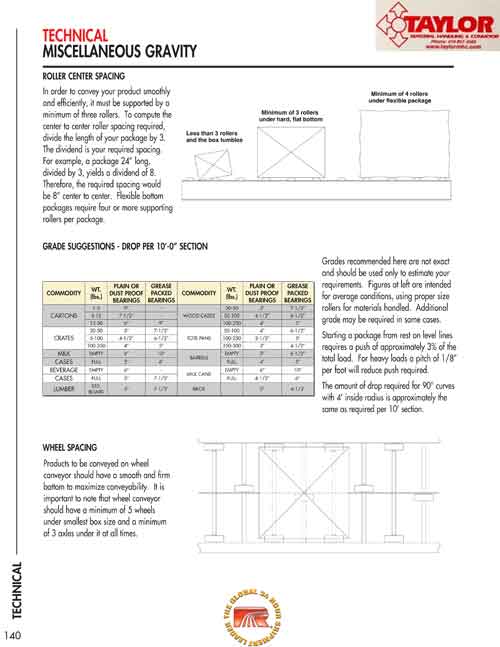

Technical Miscellaneous Gravity

-

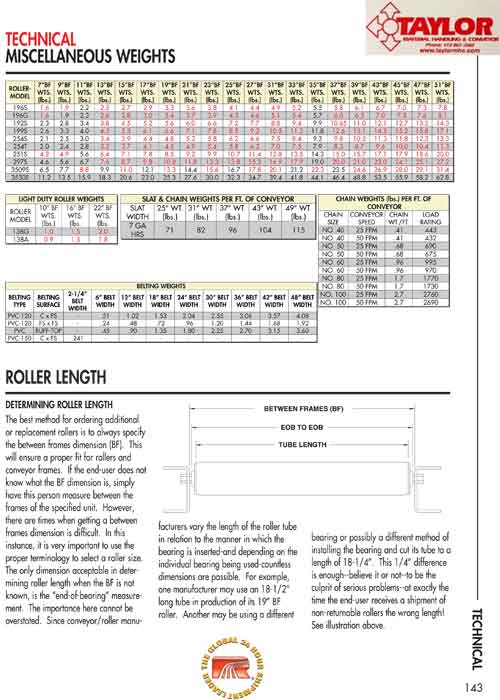

Technical Miscellaneous Weights

-

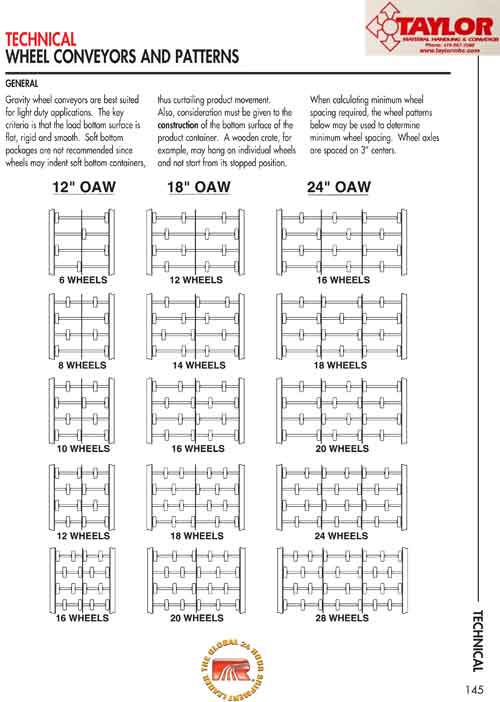

Technical Wheel Conveyors & Patterns