The Powered Roller Conveyor has revolutionized the automated conveyor industry. Motorized rollers drive the conveyors eliminating the need for drive belts, chains or line shafts. 24 VDC MDR Carton/Packaging Conveyors are available with various load capacities and roller diameters. Standard straight sections in 1 ft. increments, 30°-45°-90° curves with tapered rollers, spurs and right angle transfers. 24 VDC MDR Carton/Package Handling Products include transportation, accumulation, curves, belted zones, belt transfers and gates. MDR Conveyors are simple to install and flexible for future growth. They operate safely, quietly and are energy efficient.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Top Conveyor Distributors and Custom Integrators

Manufacturing, Material Handling, Distribution Centers, Automation, Automotive

Conveyors are used for:

Movement of materials, products and loads throughout a manufacturing or distribution facility, conveyors are horizontal, inclined or vertical devices. Product transport is powered by gravity or by hydraulic or electric power. Loads ride atop roller or a belt that travels along a fixed path with specific points for loading and discharge. Because they enable large volumes of material to be moved rapidly through process or facility, conveyors reduce labor costs by eliminating non-value-added travel time. Typical conveyor applications include movement of cases, totes or palletized loads into and out of a trailer, to and from static or automated storage systems, or from a picking area to packaging for shipping.

How are conveyors applied?

- Conveyors are applied in a variety of areas to move materials throughout a facility.

- Assembly: Moving Products through production process.

- Transportation: Moving pallets, cases and totes throughout a facility.

- Staging: Accumulating and holding items for further processing or packaging.

- Warehousing: Moving products from receiving to storage.

- Order Picking: Moving ordered products from storage to shipping areas, and completed order to trailer-loading area for distribution.

Conveyors provide a variety of benefits:

- Ergonomics: Because they do the work of load movement, conveyors eliminate the chance of operator injury from pushing or pulling a load.

- Process Flow: Conveyors can be used as a part of an assembly or manufacturing process.

- Safety: Because they move loads along a fixed path, conveyors eliminate the chance of collisions associated with a forklift or manual product movement.

- Transportation: Conveyors facilitate the internal movement of totes, cases or pallet loads throughout a facility with minimal or no labor required.

-

24 VDC Conveyors – 196 PR Series

-

24 VDC Smart Conveyors – Smart MDR

This new state of the art technology allows for zone to zone control through Ethernet/IP communication. Zone and product control is now easy to monitor and control with the new Smart MDR Conveyor. These conveyors include 1.9” and 2.5” roller sizes capable of moving a wide range of product sizes and weights. The controllers are available in programmable or fixed formats capable of handling simple to complex systems and are easily modified for future growth. Smart Conveyors are zero pressure accumulating conveyors featuring Motorized Driven Roller and controllers from Itoh Denki.

24 VDC MDR Conveyor Systems are used in many industries such as automotive, bottling and canning, chemical, corrugated, distribution, food, fiberglass, plate glass, building, materials and many other manufacturing industries.

-

Accumulation Conveyors

Accumulation Conveyors hold product in place until they are signaled to resume conveying. Accumulation conveyors may be roller, belt or chain conveyors. Applications include feeding product to a machine at a specified rate, or to hold all items in a batch until they are needed for the next process. This is useful when a line of packages need to be accumulated without pressure so that they can be utilized in a process such as loading, sorting, taping, strapping, palletizing or picking. Accumulation conveyors may be minimum back pressure or zero back pressure.

-

Automation Conveyors

Over the last 50 years, Dorner’s Low Profile, Modular Conveyor and Sanitary Conveyor product lines have evolved from a single, low profile metalworking conveyor to a wide variety of industrial, aluminum frame and sanitary, stainless steel frame conveyors. With fabric belt, modular belt, and flexible chain options, these conveyors can be configured as straights, curves, inclines, declines, and Z-frames. Taylor Material Handling & Conveyor, as a Dorner belt and sanitary conveyor distributor, has solutions for a broad range of industries including packaging, automation, food processing, manufacturing, pharmaceutical, medical, and more.

-

Belt Conveyors

Belt Conveyors are available in both slider bed and roller bed styles. Slider bed belt conveyors are utilized for the transportation of hard to convey items such as small parts or items with inconsistent shapes or sizes. These conveyors can be configured for inclines, declines, or horizontal applications. Slider bed belt conveyors are often used in packaging, shipping, inspecting, testing and assembly. Belt conveyors are ideal for handling chips, slugs, scrap wood, paper waste, boxes, packages and cartons. The troughed frame design offers integral guard rails for many trash conveyor applications. Roller bed belt conveyors typically require less horsepower than slider bed belt conveyors with similar length and loading. Each roller helps minimize friction, thus providing for greater capacities. They provide an economical method of moving medium weight products.

-

Belt Driven Live Roller Conveyors

Belt Driven Live Roller Conveyors are utilized for transporting and accumulation of items with flat bottoms such as boxes, cartons and plastic or metal totes. BDLR conveyors are an economical choice where product positioning and/or accumulation are required. BDLR conveyors are ideally suited for side loading, unloading or temporary accumulation. Its unique cam allows tread roller drive pressure to be adjusted in only seconds. The closer roller spacing that is possible with a belt driven roller conveyor is ideal for small items.

-

Chain Driven Live Roller Conveyors

Chain Driven Live Roller Conveyors are specifically designed to transport heavy duty loads such as tote pans, castings, drums, pallet loads, etc. It is especially suited for carrying loads in the presence of oil and other such contaminates. CDLR conveyors are available to accumulate loads as well. These conveyors are ideal for bi-directional applications.

-

Chain Conveyors

Chain Conveyors are designed to move products that a roller conveyor will not. Drag chain conveyors convey heavy duty unit loads and often are suited for products with unusual conveying characteristics such as pallets or specialty tote pans. Typical drag chain conveyors use two strands of chain to transport the product. Additional chain strands can be added to increase load capacities.

-

Chain & Belt Transfer

Chain & Belt Transfer can be incorporated into any gravity or powered roller applications. “O” ring and V-belt transfers are used for loads up to 400 lbs. and where product could be damaged by strands of chains. Chain transfers are ideal for heavy loads. Transfers can be designed with multiple strands of chains or belts to support large heavy loads.

-

Cleated Belt Conveyors

These units include two features (side rails and cleats) specifically designed to catch, carry and contain loose, unpackaged items like plastic parts, nuts and bolts or stampings. The cleats catch the loosely wrapped products and carry them upwards while the side rails contain the products within the cleat and the conveyor sides. Typically unboxed, loose products like plastic parts and stampings are loaded into an attached hopper and then discharged into bins or drums.

-

Conveyor Accessories

Conveyor Accessories are used in conjunction with conveyors and includes items such as rails, legs, end stops, floor supports, power cords, replacement rollers, roller stand and track wheels.

-

Conveyor Components

Conveyor Components consists of everything equipped on your conveyor as far as replacement parts and other accessories go. Whether you need more support legs or a couple union plates, chances are we have it. Our component offerings include rollers, pulleys, belting and drive assemblies. Guard rails, end stops, supports and ceiling hangers are also available. (Note: See electrical control section for valves, photo eyes and other electrical components.)

-

Custom Conveyors

Custom Conveyors are designed and manufactured in our facility, using the latest manufacturing technologies, to meet the specific needs of our customers. All custom conveyors can be manufactured for any industry and are fully assembled, tested and inspected prior to shipment. To view some examples of the many conveyors we have manufactured, please refer to the custom equipment page.

-

Gravity Roller Conveyors

are used in carrying light to medium weight packages and cartons when a drive is not required to Gravity Roller Conveyors move products from “a” to “b.” They are an economical solution for temporary or permanent applications. Numerous accessories are available such as curves, spurs, pop-up stops, supports, ceiling hanger brackets and side rails. Optional roller materials include galvanized, stainless steel or plastic coated. Side frames are available in aluminum, mild and stainless steel.

-

Hinged Steel Belt Conveyors

the steel belt conveyor is the most reliable and versatile conveyor mainly used to convey scraps of metal in all shapes and sizes. It is commonly used in machining operations to convey the product vertically into scrap hoppers. Hinged steel belt conveyors are available with low profile frames and various styles of belts.

-

Line Shaft Conveyors

Line Shaft Conveyors are powered by a shaft beneath the rollers. These conveyors are suitable for applications up to 75# such as cardboard boxes and tote boxes. A single shaft runs below the rollers running the length of the conveyor. Curves, spurs and a number of accessories may be driven by a single drive. Advantages of this conveyor are quiet operation, easy installation, moderate maintenance and low expense. Line shaft conveyors are also extremely safe for people to work around because the elastic belts can stretch and not injure fingers should any get caught underneath them. Moreover, the spools will slip and allow the rollers to stop moving if clothing, hands or hair gets caught in them. Line shaft conveyors are an excellent choice for accumulation of boxes and totes.

-

Low Profile Conveyors

Straight-low profile conveyors for a wide range of applications are available for shipment in 24 hours. Commonly used in manufacturing, metal stampings, bottling, injection molding and packaging work cells. Frame depths as low as 1-3/4” with 1-1/2” diameter pulleys are available for small transitions. Round, hex, “V” or conventional fabric belts are standard from 1” wide to 24”. Conveyor lengths range from 18 inches to 30 feet. Low profile belt conveyors can be built from steel, stainless steel or extruded aluminum modular components.

-

Overhead Conveyors

Overhead Conveyors are known as one of the most cost efficient ways to convey a product from one point to another. Most commonly found in manufacturing facilities used on finishing lines, parts accumulation, assembly and shipping lines. Overhead conveyors are also found in distribution warehouses conveying totes, cartons and trash to a disposal area. Overhead conveyors are available in enclosed track, I-Beam, as well as power and free configurations. Elevate your operation with automation.

-

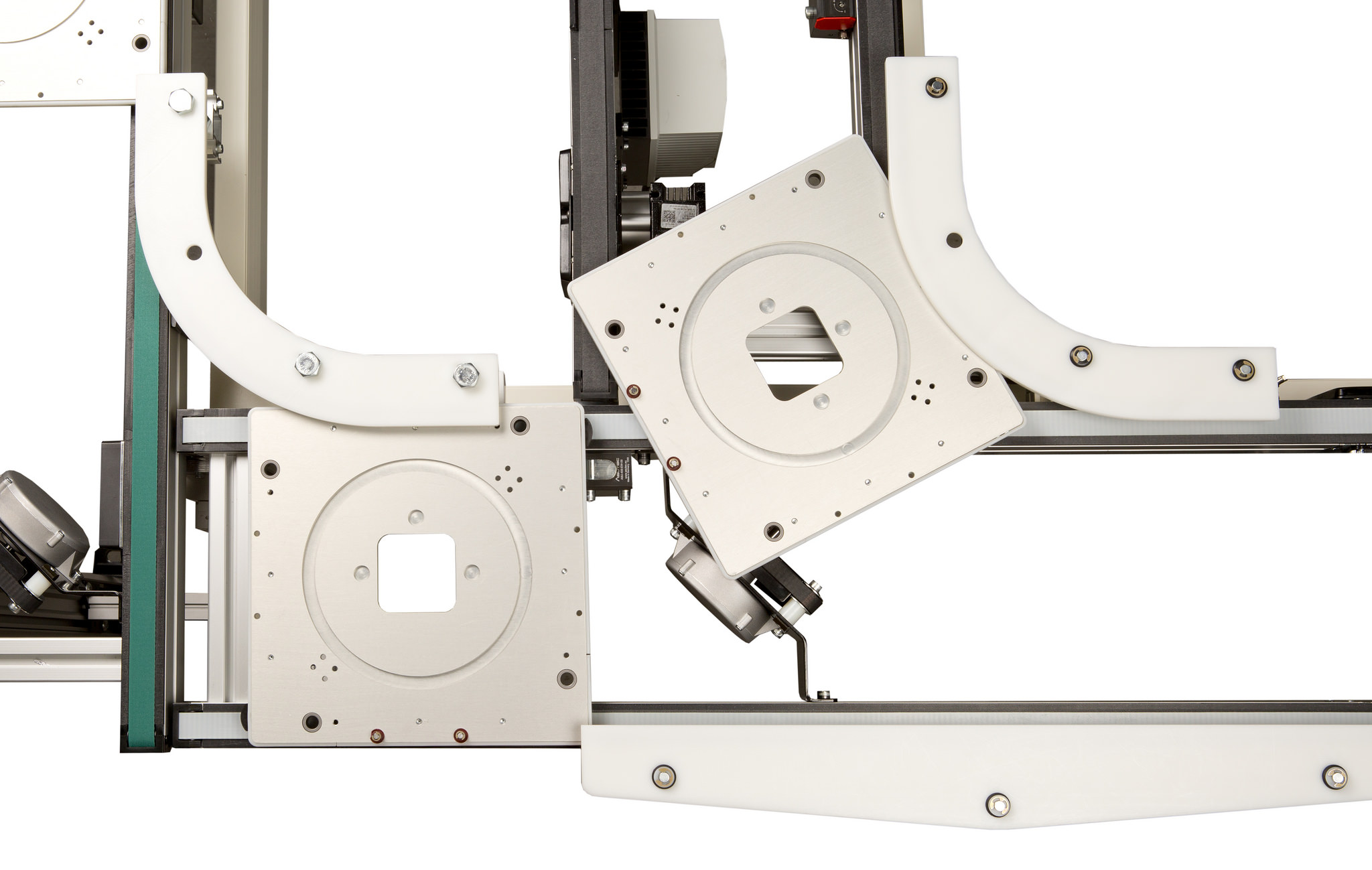

Pallet Handling Systems

Every system has unique challenges, our vast range of products turn your challenge into our opportunities. Turnkey solutions are available to dispense, convey, transfer, rotate, upend and stack pallets – empty or with product. Equipment is available using traditional 460 VAC drive units as well as the 24 VDC motor driven roller product line. Electrical control systems are available pre-mounted, wired and programmed for basic plug and play zero pressure accumulation of product.

-

Plastic Modular Belt Conveyor

can be utilized wherever there is a need to handle heavy loads for accumulation, where drainage or airflow are required, or where there is a need to transport around a curve. They are also used in applications such as transporting, turning, merging, diverting, or accumulating products. Plastic Modular Belt Conveyors are designed to handle various sizes of bottles, cans, jars, cartons and cases with maximum efficiency and minimum pressure. These conveyors are used in a variety of processing applications including product filling, labeling, weighing or inspection. Belting is available in a variety of materials, many which meet FDA and/or USDA approval. They are ideal for direct food contact and wash-down applications. The plastic belts are constructed of plastic modules and hinge rods, and are driven and tracked by plastic sprockets. This provides them the following valuable qualities: corrosion resistance, positive drives, self-tracking, high strength, low friction, abrasion resistance, and the ability to be designed in almost any width and length. Belts are available in flat top, friction top, and roller top or with a variety of flights or side guards. Frames are available in aluminum, mild and stainless steel, so they can be utilized for applications from food processing to industrial production. Plastic Modular Belt Conveyors are of modular design giving you a virtually unlimited variety of configurations. This makes them ideal for incorporation into more complex processes and for future plant modifications.

-

Portable Conveyors

Portable Conveyors are great for quick and easy set up. They can be used almost anywhere, for anything because they are light weight and durable.

-

Slat Conveyors

Slat Conveyors are commonly used in assembly line operations where product moves at a slow rate of speed through several operator workstations. They are used for transportation, accumulation, side loading/unloading and production lines. They are also used where roller chain is needed to reduce friction and allow heavier loads.

-

Sortation Conveyors

Sortation Conveyors are used in distribution facilities in an automated order fulfillment process to sort items to packing stations. Another common use is to sort finished goods orders to specific destinations or shipping dock doors. Sorting conveyors are comprised of flow deflectors, wheel diverters, roller belt diverters, pushers, transfers and shoe sorters. High speed sorters were designed in response to an increasing demand for high speed distribution equipment. Single side sorting rates can be accomplished up to 250 cartons per minute and double side sorting up to 150 cartons per minute.

-

Table Top Chain Conveyors

Table Top Chain Conveyors are used in applications such as transporting, turning, merging, diverting or accumulating products. Table top chain conveyors are designed to handle various sizes of bottles, cans, jars, cartons and cases with maximum efficiency and minimum pressure. Table top chain conveyors are used in a variety of processing applications including product filling, labeling, weighing or inspection of meat, bakery products, food handling, pharmaceuticals and small parts markets. Belting is available in a variety of materials, many which meet FDA and/or USDA approval. Frames are available in aluminum, mild and stainless steel, so they can be utilized for applications from food processing to industrial production. Most table top chain conveyors are of modular design giving you a virtually unlimited variety of configurations. This makes them ideal for incorporation into more complex processes and for future plant modifications.

-

Vertical & Spiral Conveyors (Vertical Conveyors)

Vertical Conveyors are designed to convey a product around obstacles whether it is from floor to floor or just another conveyor line at a constant speed. Vertical conveyors are also known as freight or material lifts, pallet lifts, tote lifts, modular box lifts. Applications include mezzanines, distribution facilities, warehouse and storage, manufacturing, schools, universities, hospitals and government facilities. Vertical conveyors are designed to handle boxes and totes all the way up to 12,000# loads. Vertical conveyors have a smaller footprint than an inclined conveyor, concerning valuable floor space. Spiral Conveyors utilize a continuous belt to elevate products without any transitions. Ideal for unstable products and high production rates.

-

Wire Mesh Belt Conveyors

A conveyor line basically unaffected by extreme heat and cold, making them ideal for transporting product through ovens or freezers. The open area of wire mesh belt facilities effectiveness in cooling, coating, draining, heating and drying processes. Wire mesh belts are available in a variety of materials including stainless steel for food handling and wash down applications.