Dorner’s family of industrial conveyors

offer numerous features to streamline

production and improve throughput in

your manufacturing line. When you need

product positioned in an exact place at a

precise time, you can rely on a Dorner

conveyor.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Belt Conveyors, Sanitary Conveyors

Dorner, Low Profile, Modular, Precision Move, SmartFlex, Backlit, FlexMove, Precision Move Pallet Systems

Over the last 50 years, Dorner’s Low Profile, Modular Conveyor and Sanitary Conveyor product lines have evolved from a single, low profile metalworking conveyor to a wide variety of industrial, aluminum frame and sanitary, stainless steel frame conveyors. With fabric belt, modular belt, and flexible chain options, these conveyors can be configured as straights, curves, inclines, declines, and Z-frames. Taylor Material Handling & Conveyor, as a Dorner belt and sanitary conveyor distributor, has solutions for a broad range of industries including packaging, automation, food processing, manufacturing, pharmaceutical, medical, and more.

Dorner’s wide variety of belt, modular belt, and flexible chain conveyors are designed to move your product to the exact location, at the exact time and in the exact position it needs to be for the next phase of the production line. With benefits such as industry best product transfers, unique elevation changes, and in-house belting capabilities, Dorner is leading the market in precision conveyance. Learn More about Dorner. (http://taylormaterialhandling.dornerconveyors.com)

Using Dorner’s Online Conveyor Configurator, you can design and engineer simple or complex conveyors to meet your needs in minutes. The industry leading tool delivers a complete 3D CAD assembly model for instant validation of fit. Check out D-Tools and build your conveyor today! (https://taylormaterialhandling-tools.dornerconveyors.com)

10 YEAR WARRANTY

At Dorner, all of the Belt and Sanitary conveyor designs are engineered and tested to ensure trouble free performance and reduce the cost of ownership. In this way, Dorner can offer every customer an Industry Leading Warranty. No other company in the industry offers a longer warranty. A 10 year limited warranty to the original purchaser against defects in material and workmanship under normal use, proper maintenance and cleaning. We will repair or replace the defective parts. Normal wear is not warranted. Dorner is not responsible for labor, freight or duties associated with the replacement of defective parts. Unauthorized modifications to the equipment or using non-Dorner supplied replacement parts shall void the warranty. Equipment manufactured by others is covered by the original manufacturer’s warranty.

Dorner does not warranty for merchantability or fitness of a particular purpose. Dorner does not warranty loss or damage to equipment, product, production, income, or profits and is not liable for direct, incidental, indirect, special or consequential damages, or any damages to persons or property.

Conveyor Applications & Solutions

Dorner offers a wide variety of industrial, aluminum frame and sanitary, stainless steel frame conveyors. With fabric belt, modular belt, and flexible chain options, our conveyors can be configured as straights, curves, inclines, declines, and Z-frames. All Dorner conveyors are built-to-order and ship in as little as 72 hours!

-

Industrial Automation Solutions

-

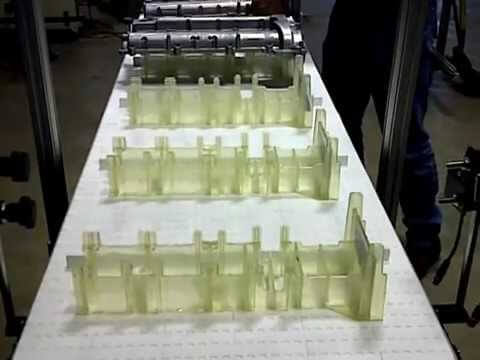

Pallet System Conveyors

Pallet system conveyors are ideal for many

automation-focused applications that

require exact movements and positioning of

parts, as they can be set-up or programmed

to start and stop at specific intervals to sync

up with robotic interaction or other

processes. -

Stainless Steel Sanitary Conveyors

Dorner’s precision hygienic conveyor

lines, AquaGard and AquaPruf, are

designed for fast, safe, and effective

sanitation and protection from

contamination. Constructed with

stainless-steel frames and available in

belt, modular belt, flexible chain, and

positive drive options.

1x Series Miniature Belt Conveyors

Dorner’s 1100 Series miniature conveyor has one of the lowest profiles in the market. The conveyor is designed for small or lightweight part handling and it can easily fit inside machinery and equipment. With Clean Room Class 100 Certification and FDA approved belting, it is ideal for pharmaceutical, medical and life science applications.

-

1100 Series Miniature Belt Conveyors

Dorner’s 1100 Series miniature conveyor has the lowest profile in North America. The conveyor is designed for small or lightweight part handling and it can easily fit inside machinery and equipment. It is ideal for pharmaceutical, medical and life science applications.

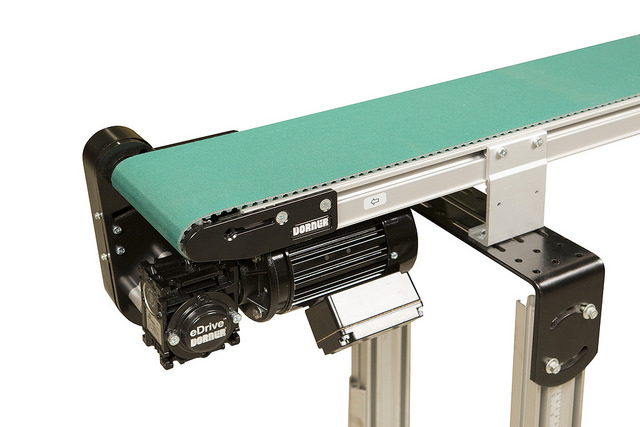

2x Series Belt Conveyors

Dorner’s 2200 Series low profile, high performance fabric and modular belt conveyors feature a high speed nose bar transfer option, a durable single piece frame design, universal T-slots, and a wide range of belting and guiding options. The 2200 Series Line is engineered for small to medium sized parts, precision applications and flexible layouts. This conveyor system is comparable and interchangeable with FlexLink conveyors.

-

2200 Series Belt Conveyors

Dorner’s redesigned 2200 Series Belt Conveyors are stronger, faster and more flexible. They feature a high speed nose bar transfer option, an improved single piece frame design, universal T-slots, and additional belting and guiding options. The 2200 Series LPZ Conveyor is also a new addition to this line.

-

2200 Series Modular Belt Conveyors

Ideal for applications in the metalworking, packaging, assembling and general manufacturing industries. Ladder-style, open frame construction for water and chemical drainage and air cooling. All belts fully contained in UHMW guiding for maintenance free tracking.

-

2200 Series Precision Move Belt Conveyors

Precision Move conveyors provide greater product control and capacity to automated applications. With positively driven belting this ensures the belt does not slip and allows for high load capacities. It also provides positive tracking along the entire length of the conveyor.

-

2200 Series Certified UR Solution

Easily integrate Dorner’s 2200 Series Conveyors and Universal Robots with UR+ Solution plug-in. Maximize automation and efficiency. Featuring the industry’s fastest lead times, with a conveyor shipping in as little as 3 business days.

-

2200 Series Gravity Conveyors

Move loads efficiently and economically without the need of power with the 2200 Series Gravity Roller Conveyor. Ergonomically designed to reduce injury and manufactured with a T-Slot that integrates with the supports, eliminating the need for mounting brackets.

-

2700 Series Belt Conveyors

Featuring an increased weight rating and extended maximum width, the 2700 Series Medium Duty is designed for medium load conveyance in material handling and eCommerce applications. This conveyor includes v-guiding and precision belt tracking to eliminate belt sway even when the conveyor is wider than it is long.

The lightweight aluminum frame design makes the 2700 ideal for AGV/AMR applications and can carry a heavier payload without weighing down the robot. The increased width and low profile mounting also allow this conveyor to fit into smaller spaces while maintaining the strength needed to convey larger products.

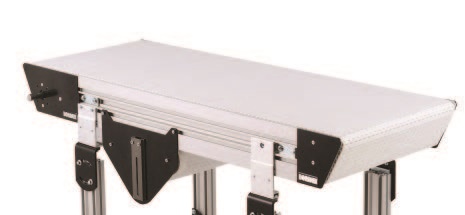

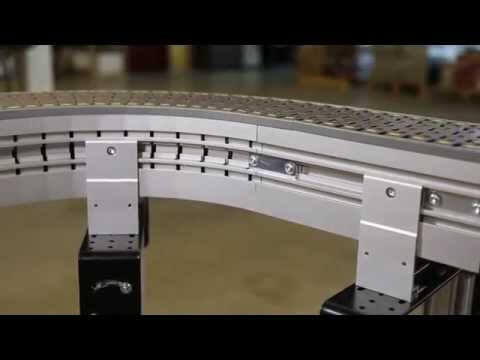

3x Series Belt Conveyors

Dorner’s 3200 Series heavy duty, low maintenance conveyors that are ideal for medium to heavy sized parts, precision applications, bulk handling and both automated and manual assembly. Available in both fabric and modular belts, 3200 Series conveyors are designed for high speeds, long runs and up to 4 curves per conveyor. Every business needing a magnetic conveyor in its facility has a specific product to run. Therefore, no two solutions will work the same for different companies. A company moving nails, screws, bolts and other small objects will not need the same magnetization as a company moving larger, heavier magnetic parts. Every conveyor features unique magnetic chips configured to handle the required product.

-

3200 Series Belt Conveyors

Heavy duty low maintenance fabric belt conveyors. Available in a variety of belt styles including flat belt, cleated, sidewall cleated, and rib top. V-guided belt tracking virtually eliminates the need for tracking adjustments. iDrive option is a space saving way to operate the conveyor.

-

3200 Series Modular Belt Conveyors

With a sleek design, heavy load and high speed capabilities, and the option for up to 4 curves. Optional Nose Bar tail available at either end for small part transfers.

-

DC Move Heavy Duty Belt Conveyors

The DCMove Belted Conveyor features an economic painted steel frame with options for a variety of fabric or rubber belting. This new conveyor system is also built with an internally mounted motor within the tails, further reducing the conveyor’s footprint and providing an easy-to-integrate conveyor package.

-

3200 Series Precision Move Belt Conveyors

Ideal for Precision Part Movement, Small Part Handling and Positioning, Automated and Manual Assembly, Machine Integration, Robotic Pick-N-Place and Precision Indexing

-

3200 Series Conveyors w/ ARB Intralox Belting

A low maintenance solution for increasing system reliability. Handle multiple product sizes without the need for changeover. Belt options include low and high friction rollers and passive and activated rollers.

7x Series Conveyors (Sanitary)

Dorner’s line of sanitary conveyors are designed to improve your food safety. With Dorner’s hygienically designed conveyors, you can have confidence in your food handling equipment and less worry about product quality. Features such as removable wear strips, belt lifters and frame cut outs allow fast access to the conveyor frame, meaning our conveyors clean up two times faster than the competition.

-

AquaGard GT Series Conveyors

Industry ready stainless steel flexible chain conveyor.

-

AquaGard LP Series Conveyors

Sanitary conveyor rated for low pressure wash down with soap and water cleaners.

-

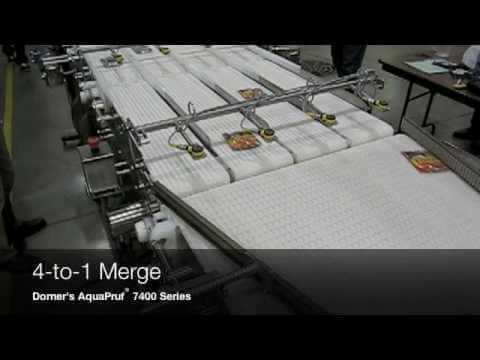

AquaPruf Series Conveyors

Tool-less disassembly. Cleaning prep in under a minute, complete disassembly in less than 3 minutes

Optional frame cut-outs and belt lifters for continuous access to inside of the conveyor. Tip-up tails allow for quick release of belt tension. Continuous TIG-welded 304 stainless steel frame. -

AquaPruf VBT Sanitary Conveyors

This vertical belt technology is used for elevating bulk products like vegetables and fruits, popcorn, grains and nuts, pet food, pharmaceuticals, and small packages. As a sanitary, vertical conveyor belt system, it’s ideal for food, pharmaceutical, chemical industries, and all sanitary environments as it carries out a wide range of applications.

-

Ready-To-Eat Sanitary Conveyors

At the heart of a Dorner RTE conveyor system is a TIG welded, Stainless Steel, hygienic conveyor with a tensionless, positive drive, belt system. Each system is custom designed to meet exact length, width and height requirements. Dorner’s innovative accessory mounting system allows for easy attachment of accessories and add-ons. Each conveyor is thoughtfully designed to balance worker safety with ease of access.

-

AquaPruf Sanitary Gravity Roller Conveyors

Frame is constructed of continuous TIG welded 304

stainless steel for durability in tough applications.

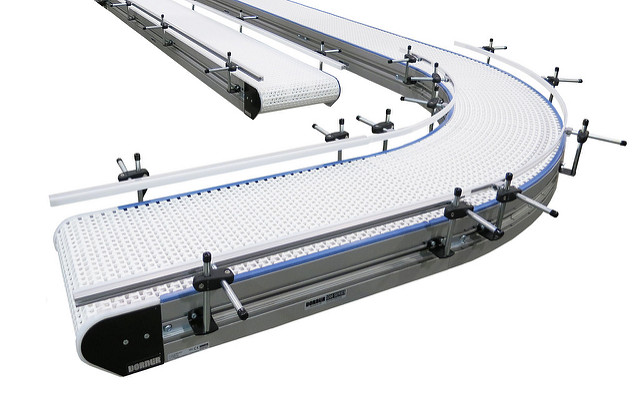

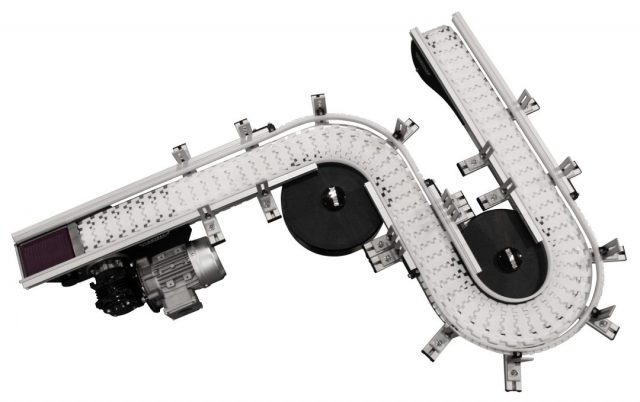

FlexMove Conveyors

Dedicated to high quality, innovative designs and comprehensive conveyor platforms, we deliver products equipped to accommodate virtually any material handling application and provide efficient solutions for a wide range of manufacturing industries. FlexMove Conveyors offer a variety of options with unique features, such as flexible chain with cleats, rollers, friction pads, steel top, anti-static and also fabric belts.

-

FlexMove Conveyors

FlexMove conveyors are available in 4 standard widths in standard flat top or friction insert chain. Capable of multiple curves as well as inclines and declines on a single conveyor. Inclines and Declines are available from 5 degrees up to 30 degrees.

-

FlexMove Helix Conveyors

Compact spiral & helical curve, flexible chain conveyors. Guiding options include aluminum high side and fully adjustable. The small footprint maximizes valuable floor space.

-

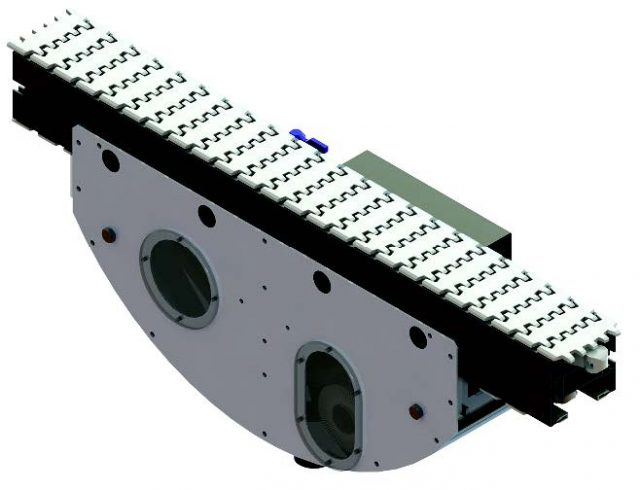

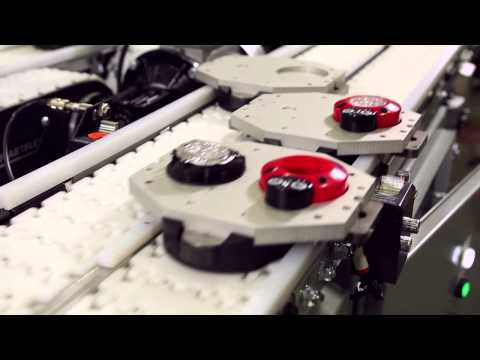

FlexMove Pallet Systems

Modular Design allows for simple configuration and ease of interface. Pallet Stops are available in cushioned and non-cushioned models. Lift & Locate Module lifts from outside of conveyor – provides 200 lbs. of holding force.

-

FlexMove Twist Conveyors

Rotate products easily and efficiently with flexible chain twist conveyors. Provides product rotation for access to multiple sides of packages. No change over –can handle multiple package sizes at the same time. Available Widths: 65, 85, 105, 180 mm wide.

-

FlexMove Wedge Elevators

Our Wedge Conveyors are used to take products from production floor level to a higher level or vice versa. Products are wedged between opposing conveyors

aligned vertically or horizontally and are moved swiftly but securely. -

FlexMove Stainless Steel Conveyors

Stainless Steel Construction is ideal for corrosion resistant applications or packaging lines. Provides capability for vertical incline with minimal floor space. Features modular framing for future add-on capability and production line changes. FlexMove Solutions eliminates unnecessary cutting, inventory and waste.

-

FlexMove Wet Cleaning Modules

Wet Cleaning Module provides continuous

cleaning of conveyor chain for applications

with liquid or product overfill or package

breakage. Water jets spray outside and inside of the

conveyor chain. -

FlexMove Dry Cleaning Modules

Dry Cleaning Module provides continuous

cleaning of conveyor chain for dry applications

with powder, dust or other dry contaminates. Slave Driven Rotary Brush scrubs chain surface,

compressed air blows off particles, and vacuum

extracts dust. -

FlexMove Side Acting Merge Modules

Two-to-one lane merging without the need

for control logic. First in, first out style merge. Opposite lane will proceed once the first lane

exits or large product gap exists. -

FlexMove Clamping Modules

Pneumatic clamping actuator, mounted on

both sides of the conveyor, holds back and

paces product. Ability to pace products back to back. Ideal for totes, boxes, bottles. -

FlexMove Helical Plain Bend Conveyors

Reduces conveyor footprint saving valuable floor space. Allows incline or decline through corners and straight. Patented side roller chain reduces corner friction. Provides capability for product buffering in corners. Ideal for incline or decline in tight spaces.

-

FlexMove Puck & Package Divert/Stop Modules

Pneumatic stop for pacing pucks or packages. Two Models: Vertical Blade Stop; used in pairs as an alternating escapement for pacing round or rounded edge rectangular pucks. Horizontal Squeeze Stop; used in combination with Vertical Blade Stop for pacing product without rounded edges. Compatible with round or rectangular bottles, containers or pucks.

Pallet Systems

Dorner’s Pallet System conveyors simplify product flow and control with features such as a unique pin tracking system, industry compatible pallet sizes and innovative modules. Our 2200 Series Precision Move Pallet System conveyor and our FlexMove Pallet Systems are advanced in pallet traffic management and are specifically designed to increase efficiency, reduce downtime in automation processes, and provide the accurate conveying.

-

FlexMove Pallet Systems

Our highly advanced FlexMove Pallet Systems are flexible conveyors with pallets for product routing and control.

-

DualMove Pallet Systems Conveyors

Our highly advanced DualMove Pallet System for assembly automation is ideal for increasing efficiency, generation, and precision of pallet traffic. Additionally, it reduces downtime costs that could disrupt production.

-

ERT 150 Conveyors

Our precision edge roller pallet and tray handling conveyors provide efficient, non-contact zoning for small & light-load assembly automation applications. They feature a clean, open roller design and are ISO Class 4 verified for cleanrooms.

-

ERT 250 Conveyors

Our precision edge roller pallet and tray handling conveyors provide efficient, non-contact zoning for medium & heavy load assembly automation applications. They feature a clean, open roller design and are ISO Class 4 verified for cleanrooms.

Conveyor Solutions (Application Specific)

-

2200 Series Metal-Free Zone Conveyors

Safety is a key concern for industries such as food packaging, making it crucial to use the right equipment to ensure that food inspection is completed to the highest standard. Dorner offers metal free zone conveyors for food inspection. To do this, we offer conveyors that can be integrated with a metal detector. This type of equipment can make certain that the food on the line is safe and free from metal and other foreign objects that may cause contamination. A metal detector and conveyor can help protect your products and customers.

-

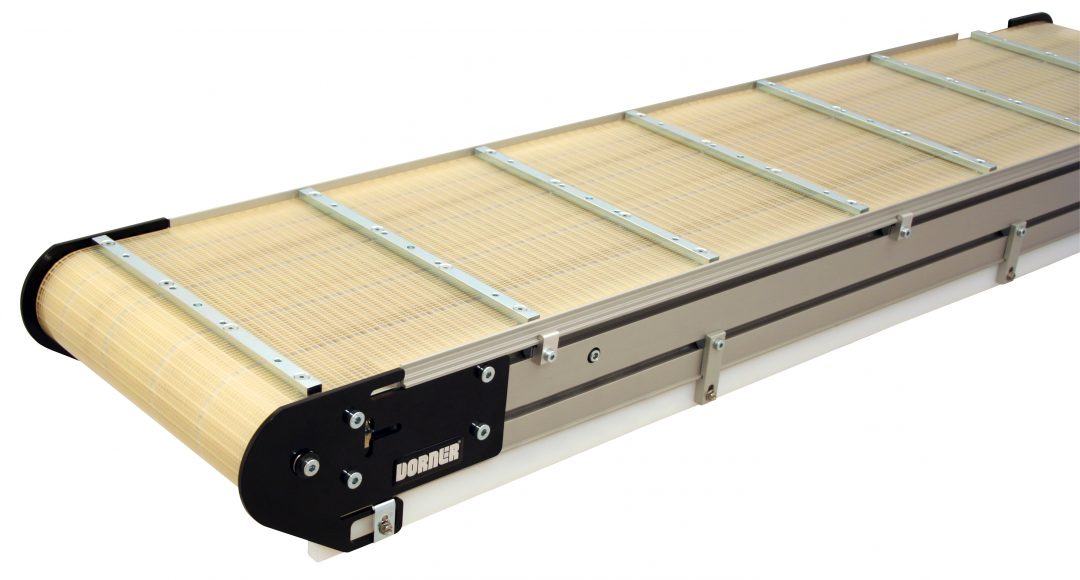

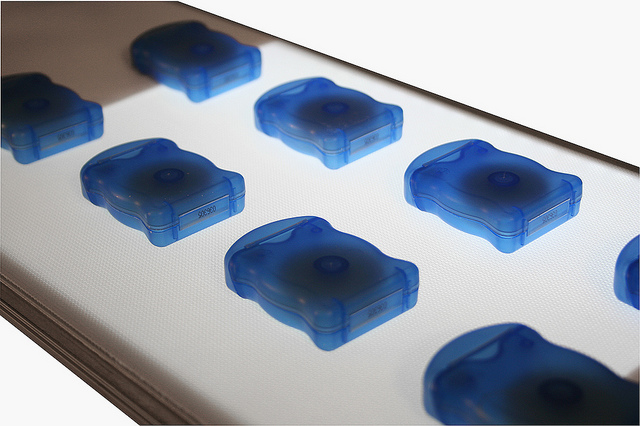

Backlit Conveyors

Light fixture is installed inside the conveyor frame and emits light through a translucent belt. Provides enhanced contrast between product and conveyor belt for visual inspection and vision system interface. Parts can be stopped directly over the lighted section or continue through uninterrupted

-

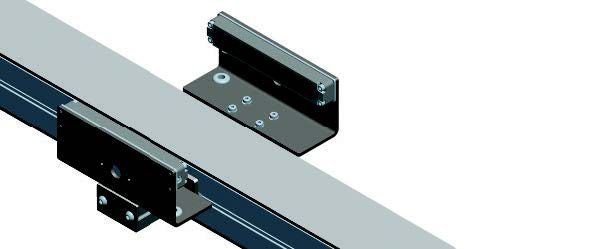

Common Drive Conveyors

Conveyors move at same relative belt speed. Creates single lanes for handling parts. Wide parts or pallets can be carried by each conveyor to allow access from below. Conveyors can be of different widths and lengths.

-

Lift Gate Conveyors

If you are looking for a way to improve access and efficiency in your facility, look no further than Dorner’s lift gate conveyors. Our lift gate conveyors are designed to provide safe and fast walk-thru access while maximizing your usable space. Many of our conveyor systems can be customized to feature lift gates, granting you access where you need it most.

-

Magnetic Conveyors

Our magnetic conveyors are built to meet the needs of our customers requiring magnetic conveyor solutions to achieve peak efficiency and productivity in their businesses. Magnetic belt conveyors ensure complete precision and control for magnetic materials being moved down your business’ production line. When working with ferrous materials, having a conveyer that uses an industrial magnet belt to control the position of parts for processing is crucial to achieve high rates of precision and speed.

-

Vacuum Belt Conveyors

When your products or components are small, lightweight and moving at a steady speed, you need a transfer solution that will keep things on track, literally. Vacuum conveyors use suction to hold items of all sizes in place as they move along, up and down the belt.

- +Product Literature

- +Application Photos/Videos

-

Dorner Photo Gallery

-

Dorner By Columbus McKinnon

-

1100 Series Engineering Manual

-

2200/2700 Series Engineering Manual

-

3200 Series Engineering Manual

-

AquaGard GT Series Engineering Manual

-

DC Move Engineering Manual

-

AquaGard LP Conveyor Engineering Manual

-

AquaPruf Conveyors Engineering Manual

-

DualMove Pallet Systems Engineering Manual

-

ERT 150 Conveyor Engineering Manual

-

ERT 250 Conveyors Engineering Manual

-

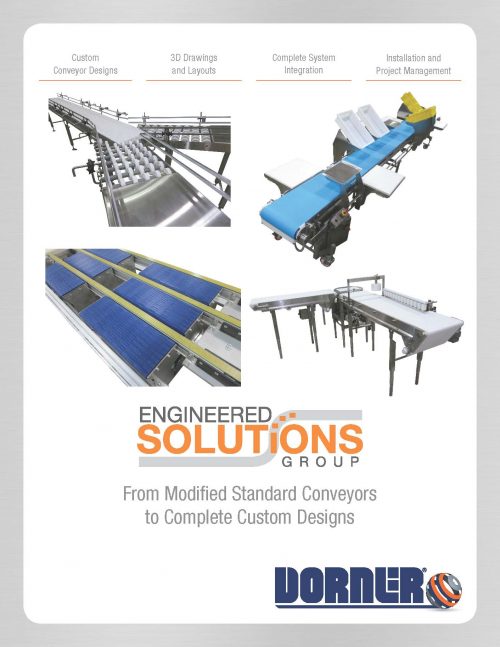

Engineered Solutions

-

Parts & Service Brochure