is designed for straight running applications. This unit is capable of supporting various styles of plastic belts designed to handle general transport applications in light duty production and packaging operations.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Plastic Modular Belt Chain Conveyors

Straight, Curved, Horizontal, Inclined

Plastic modular chain conveyors provide the most flexibility in design and the lowest total cost of ownership versus all other conveyor types. Plastic chain has more chain link options to match the chain to the customer’s product specifically, for the best results possible. Belt conveyors can only go where they can be stretched between two rollers. This limits them to discrete straight and curved modules. Every time the product has to change direction, a new conveyor is required. This is not the case with modular chain conveyor systems. Let Taylor Material Handling & Conveyor guide you to the correct solution for your application. We are authorized Dorner, Nedco, New London Engineering, Omni Metalcraft, and Spantech distributors/dealers representing the very best in plastic modular chain conveyors.

10 YEAR WARRANTY

At Dorner, all of the Belt and Sanitary conveyor designs are engineered and tested to ensure trouble free performance and reduce the cost of ownership. In this way, Dorner can offer every customer an Industry Leading Warranty. No other company in the industry offers a longer warranty. A 10 year limited warranty to the original purchaser against defects in material and workmanship under normal use, proper maintenance and cleaning. We will repair or replace the defective parts. Normal wear is not warranted. Dorner is not responsible for labor, freight or duties associated with the replacement of defective parts. Unauthorized modifications to the equipment or using non-Dorner supplied replacement parts shall void the warranty. Equipment manufactured by others is covered by the original manufacturer’s warranty.

Dorner does not warranty for merchantability or fitness of a particular purpose. Dorner does not warranty loss or damage to equipment, product, production, income, or profits and is not liable for direct, incidental, indirect, special or consequential damages, or any damages to persons or property.

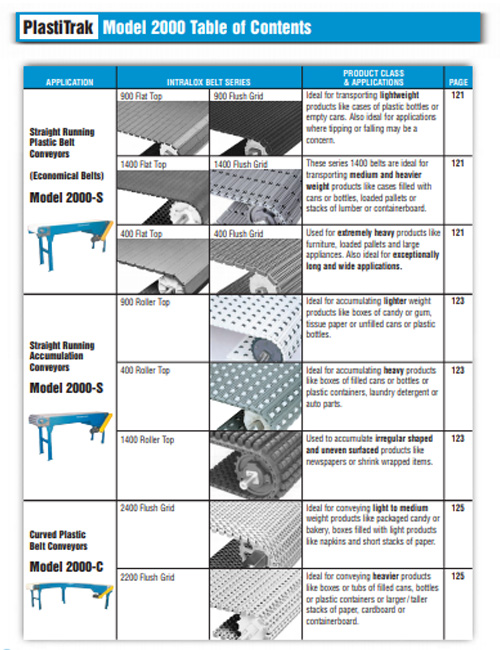

Plastic Modular Belt Conveyors

-

Model 2000-S

-

Model 2000-S Accumulation

is designed for straight running applications. These pages will show the various styles of belts designed for accumulations of products ranging from boxes of candy to laundry detergent to accumulations of irregular shaped products like newspapers or magazines.

-

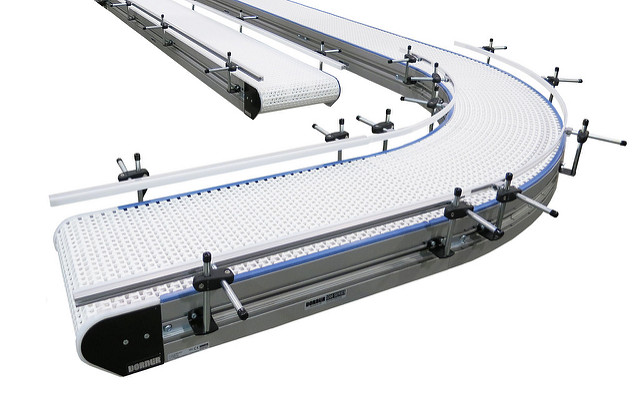

Model 2000-C

Used in applications that require 90-180 degree horizontal curves. This modular chain conveyor conveys product around curves without adding additional drives while reducing product damage with less transition areas.

-

Model 2000-CF

Curved and Flighted Conveyors are used to convey packaged products such as candy, baked goods and paper products. These products can be conveyed vertically, around curves and horizontally with one drive.

-

Model 2000-F

Designed to carry small, unboxed, loose products like plastic parts, nuts, bolts, plastic bottles, cans and stampings. These units typically use flights and side guides to catch, carry and contain unwrapped, unpackaged items. The flights catch and carry the products and transport them upwards while the side guides contain them within the flights and the conveyor sides.

-

Model 2000-N

Designed the carry boxes up inclines or down declines. These units use a belt with a friction top surface rather than a cleat to move products. The nose over provides a smooth transition from the incline to the horizontal. Units should not exceed 30-degree inclines.

-

2200 Series Modular Belt Conveyors

Ideal for applications in the metalworking, packaging, assembling and general manufacturing industries.

-

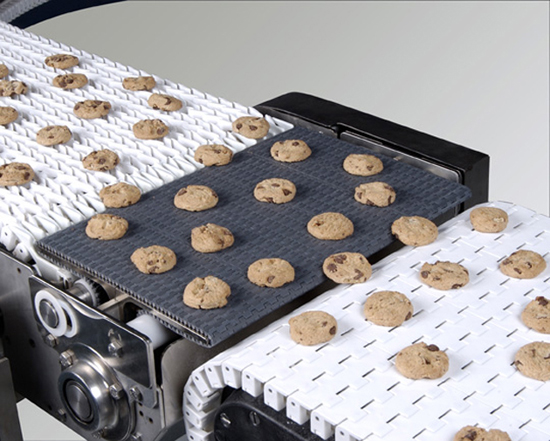

3200 Series Modular Belt Conveyors

With a sleek design, heavy load and high speed capabilities, and the option for up to 4 curves. Optional Nose Bar tail available at either end for small part transfers.

-

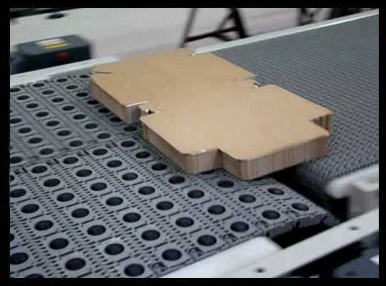

3200 Series Conveyors w/ ARB Intralox Belting

A low maintenance solution for increasing system reliability. Handle multiple product sizes without the need for changeover. Belt options include low and high friction rollers and passive and activated rollers.

-

7350 Series

The 7350 Conveyor is built for maximum flexibility with straight, curve and z-frame module options.

-

7400 Series

Straight, curved, and Z-frame models available. Curved conveyors can have up to 2 curves with curves from 15º to 180º (with up to 240º total).

-

7400 Ultimate Series

Engineered for Fast & Effective Sanitation in the most demanding environments. Optional clean in place module cleans inner and outer surfaces of belt. Cleaning channels allow for complete sanitation and access to spindles.

-

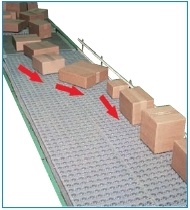

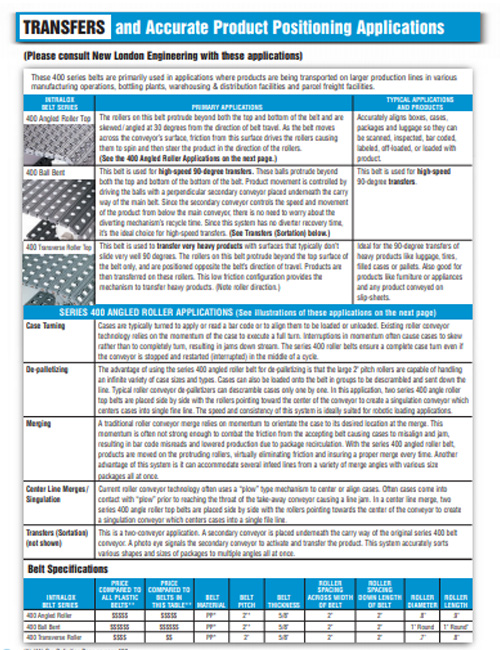

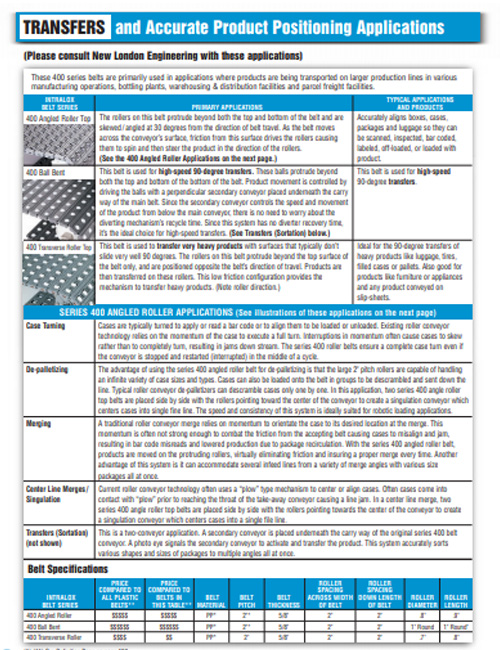

Case Turning

The angled rollers direct the boxes to the edge of the conveyor. The boxes then turn as they hit the case turner.

-

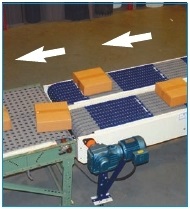

Center Line Merge

The two side-by-side angled roller belts direct to the belt’s center.

-

Merging

This system properly merges and orients packages of a variety of sizes and shapes, accommodating several infeed lanes from a variety of merge angles. The spinning rollers direct the products to the conveyor edge.

-

Spantech ST Series

The SpanTech ST-Series conveyors are straight conveyors. They are ideal for transporting packaged items, assembly work, or applications where belt conveyors have traditionally been used. The ST-Series comes with a fully assembled bed section and separate legs for quick assembly.

-

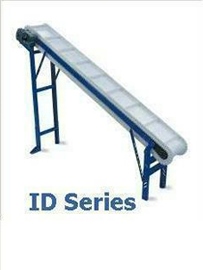

Spantech ID Series

he SpanTech ID-Series is an inclining or declining conveyor with custom lengths available. The ID-Series is offered with a straight bed section that is elevated at a continuous angle. These conveyors allow change in the elevation of various products.

-

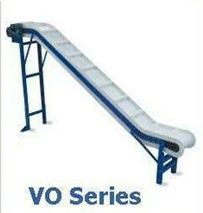

Spantech VO Series

The SpanTech VO-Series is a vertical offset conveyor. The VO-Series adds the benefit of horizontally oriented product at the beginning and the end of the conveyor. The angles of both vertical curves can be specified to fit various needs. It features optional

-

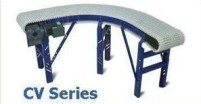

Spantech CV Series

The SpanTech CV-Series curving conveyors are ideal for those applications where you need to turn corners but floor space is limited. The CV model is a single curving conveyor with minimum end lengths. They’re engineered to have the tightest turning radius in the industry and provide dependable, nearly maintenance-free operation. The CV-Series comes with the bed section fully assembled, with legs separate for quick assembly.

-

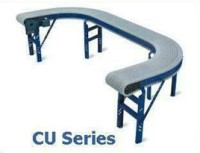

Spantech CU Series

The SpanTech CU-Series is a double curving conveyor featuring two curves in the same direction. The CU-Series allows custom design of a U-shape conveyor to fit your layout. It features variable straight lengths between the two curves, and between the curves and the ends of the conveyor.

-

Spantech CA Series

The SpanTech CA-Series curving with tangent straight section conveyors allow custom design to fit various layouts. There are three choices of turning radius and varying overall straight length coming out of the curve. They provide dependable, nearly maintenance free operation and are virtually silent while operating.

Plastic Modular Belt Transfers

-

MC-300HD Low Profile Transfer Conveyors

Straight low-profile conveyor, available for next day delivery in custom lengths ranging from 2 ft. to 20 ft. Adjustable speed standard with plastic chain on aluminum bed section.

-

Spantech MicroSpan Transfer

An innovative concept in plastic chains, developed especially for SpanTech’s powered transfer program. The stainless steel construction offers excellent wash down capability; bridge can also be lifted out for cleaning.

-

Gravity Roller / Powered Roller Transfer

Utilizes the same 0.44” roller diameter as the powered roller transfer, providing the same capabilities for small product transfer. Roller bridge can be easily lifted out and replaced to facilitate cleaning and maintenance.

- +Product Literature

- +Application Photos/Videos

-

Plastic Modular & Table Top Chain Conveyors Photo Gallery

-

2200 Series Engineering Manual

-

3200 Series Engineering Manual

-

7X Series Engineering Manual

-

Intralox vs Flat Belt

-

Intralox vs Metal Belt

-

Intralox vs. Spiral

-

Model 1000 Table of Contents

-

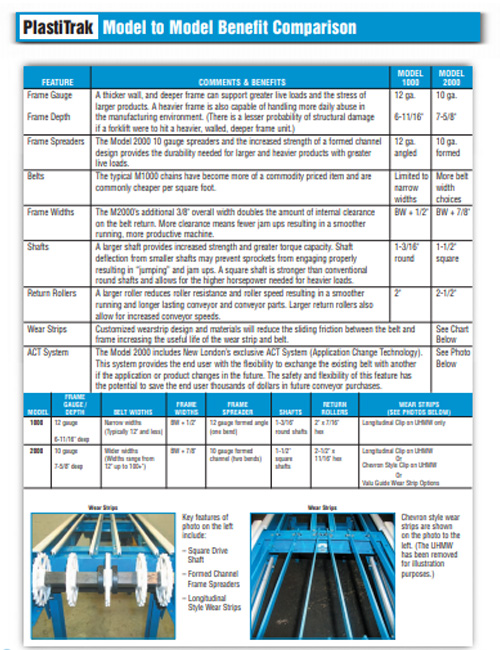

Model 1000 vs 2000

-

Model 2000 Table of Contents

-

Transfers and Accurate Product Positioning Applications