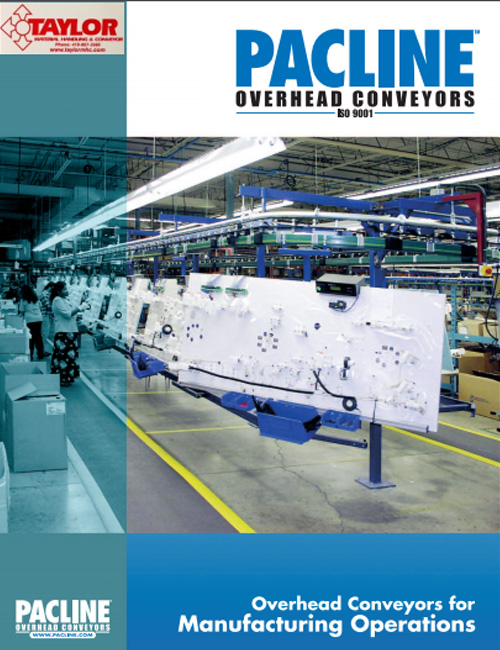

Pacline Enclosed Track Conveyors are designed to handle 50 lbs. (23 kg) from single pendants, which are standard on 6” centers. Coupling two pendants with a load bar allows up to 100 lb. loads. Distributed loads up to 30,000 lbs. can be conveyed on a 600 ft. system with only one drive.

For Over 50 Years, One of America’s Leading Integrators of Conveyor and Material Handling Equipment

Overhead Conveyors, Towline Conveyors

Pacline, Richards-Wilcox Distributors, Power & Free, Heavy Duty, Enclosed Track, I-Beam Trolley

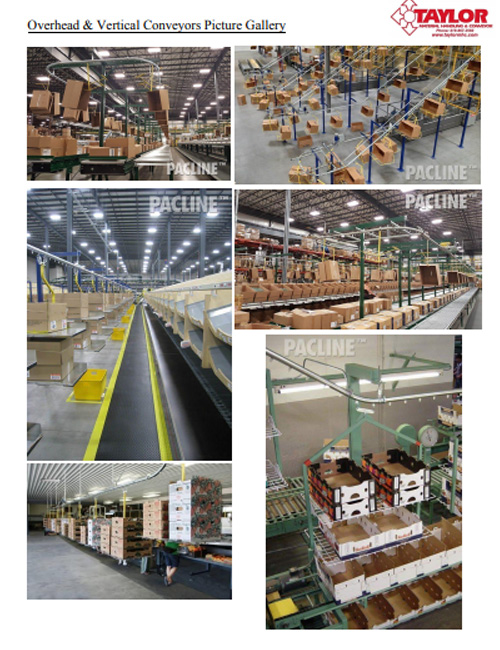

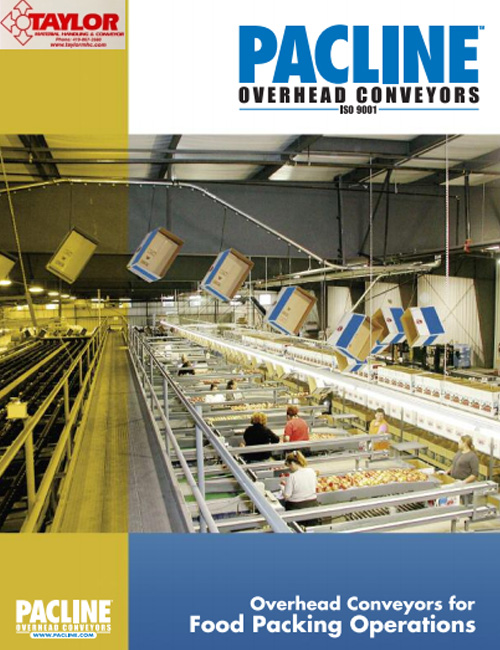

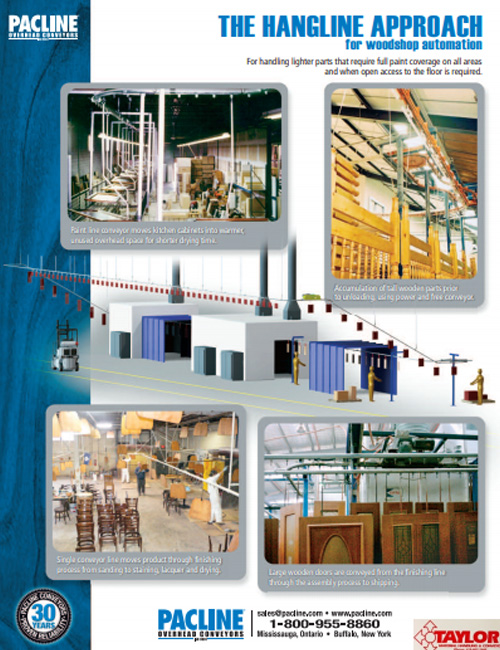

Taylor Material Handling & Conveyor is a Pacline and Richards-Wilcox overhead conveyor systems distributor with conveyors designed for a wide range of industrial material handling operations including: parts handling, overhead storage, and assembly lines in manufacturing and empty carton handling systems in distribution centers. Request a quote for a custom overhead conveyor system from us today.

-

Pacline Enclosed Track

-

Pacline Heavy Duty

Pacline’s S-60 is a high capacity, enclosed track chain conveyor designed for stability in conveying heavy duty loads; up to 220 lbs. from a single pendant. This conveyor has a unique cross shaped track section that allows for “slot-up” (inverted), “slot sideways” (side-loaded) or “slot down” applications.

-

Pacline Power & Free

For enclosed track Power and Free conveying, the S-310 is one of the most versatile power and free conveyors in the industry due to its compact design and ability to carry loads in “slot down” or “slot up” (inverted Power and Free) orientations.

-

Pacline I-Beam Trolley

Since the time of the first automobile, I-Beam overhead conveyors have brought increased efficiency to production lines. Using this proven design, Pacline has developed the PAC-BEAM™ I-Beam conveyor with improved components for low cost conveying in a wide range of applications. Pacline’s PAC-BEAM™ overhead monorail conveyors are proven to provide the lowest “cost per lb. of capacity” of all overhead conveyors.

-

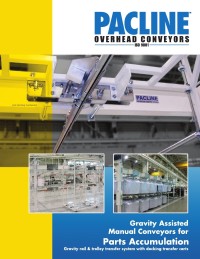

Pacline Gravity Parts Accumulation

Two methods of accumulation: rails can be monoplane with latching trolleys and rails can be slightly sloped allowing gravity to help accumulate parts. Mobile carts are custom designed to accommodate your specific part requirements. Cart activated stoppers at ends of storage rails queue parts for transfer onto mobile carts. Smooth docking guides help precisely locate carts for part transfer.

-

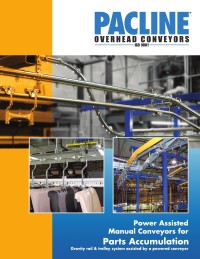

Pacline Power Parts Accumulation

In many material handling applications, the accumulation (non-synchronous) of products and the switching or routing of products between tracks may be required. Traditional power and free conveyor systems can easily do this but may be cost prohibitive. Pacline has designed a manual gravity rail and trolley system that is combined with a powered Pacline overhead chain conveyor resulting in a semi-automated system. Although this system is not fully automatic, in situations where some manual assistance by operators is acceptable then this approach may be suitable and highly cost effective.

-

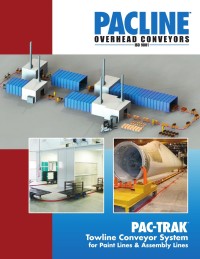

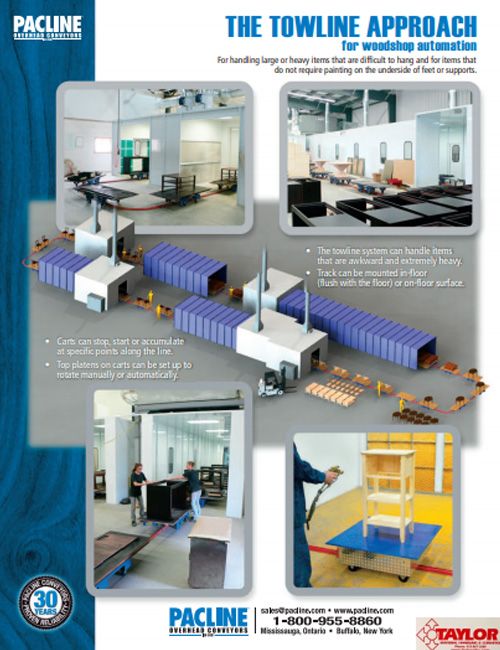

Pacline Pac-Trak Towline

The standard four-wheeled cart is propelled by a drive chain. The system can be mounted “in floor” or “on floor” with minimal cross section height. Platens can be rotated manually for easy access to all sides by operators. Platens can also be rotated automatically for close-packing in accumulation zones. Capacity is scalable from 1 lb. to 30,000 lbs. on the same conveyor.